Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during rear axle carrier sub-assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

|---|---|---|---|

| Rear wheel alignment adjustment | Calibration |

| |

| Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

|

| |

| Rear television camera assembly optical axis (Back camera position setting) | Parking Assist Monitor System | for Initialization: for Calibration: | |

| Panoramic View Monitor System | for Initialization: for Calibration: | |

| Initialize No. 1 headlight ECU sub-assembly LH | Lighting System (w/ Automatic Headlight Beam Level Control System) | |

HINT:

- Use the same procedure for the RH side and LH side.

- The following procedure is for the LH side.

PROCEDURE

1. REMOVE REAR WHEEL

Click here .gif)

2. REMOVE REAR SUSPENSION ARM COVER

Click here .gif)

3. REMOVE REAR AXLE SHAFT NUT

Click here .gif)

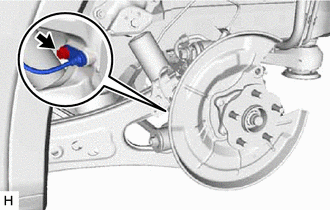

4. SEPARATE REAR FLEXIBLE HOSE

| (a) Remove the bolt and separate the rear flexible hose from the rear upper control arm assembly. |

|

5. SEPARATE REAR DISC BRAKE CALIPER ASSEMBLY

Click here .gif)

6. REMOVE REAR DISC

Click here .gif)

7. SEPARATE NO. 2 PARKING BRAKE WIRE ASSEMBLY

| (a) Remove the 3 bolts and separate the No. 2 parking brake wire assembly from the rear trailing arm assembly. |

|

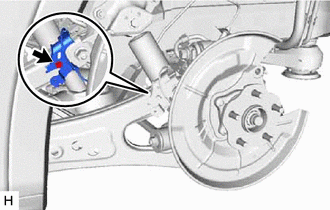

8. SEPARATE REAR SPEED SENSOR

| (a) Remove the bolt and separate the rear speed sensor from the rear axle carrier sub-assembly. NOTICE:

|

|

| (b) Remove the bolt and separate the rear speed sensor from the rear trailing arm assembly. |

|

9. REMOVE REAR AXLE HUB AND BEARING ASSEMBLY

Click here .gif)

10. REMOVE REAR TRAILING ARM ASSEMBLY

Click here .gif)

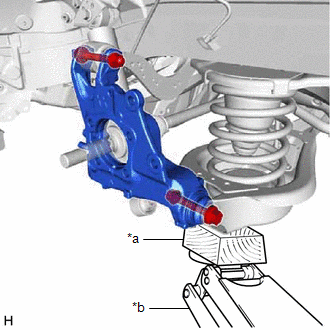

11. REMOVE REAR AXLE CARRIER SUB-ASSEMBLY

| (a) Using a jack and a wooden block, support the rear No. 2 suspension arm assembly. NOTICE:

|

|

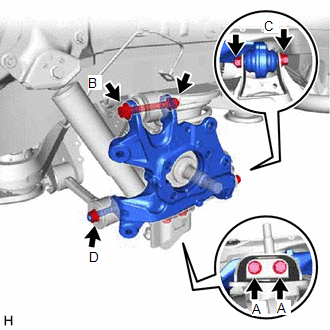

| (b) Remove the 2 bolts (A), and separate the rear lower shock absorber bracket sub-assembly from the rear axle carrier sub-assembly. |

|

(c) Remove the bolt (B) and nut, and separate the rear upper control arm assembly from the rear axle carrier sub-assembly.

NOTICE:

Because the nut has its own stopper, do not turn the nut. Loosen the bolt with the nut secured.

(d) Remove the bolt (C) and nut, and separate the rear axle carrier sub-assembly from the rear No. 2 suspension arm assembly.

NOTICE:

Because the nut has its own stopper, do not turn the nut. Loosen the bolt with the nut secured.

(e) Remove the nut (D), spacer and rear axle carrier sub-assembly from the rear No. 1 suspension arm assembly.

NOTICE:

Use wire or an equivalent tool to keep the rear drive shaft assembly from hanging down.

12. REMOVE LOWER CONTROL ARM PIN (for TMMC Made)

| (a) Secure the rear axle carrier sub-assembly in a vise using aluminum plates. NOTICE: Do not overtighten the vise. |

|

(b) Using a hammer, remove the lower control arm pin from the rear axle carrier sub-assembly.

Components

Components

COMPONENTS ILLUSTRATION *1 REAR AXLE HUB AND BEARING ASSEMBLY *2 REAR AXLE SHAFT NUT *3 REAR DISC *4 REAR DISC BRAKE CALIPER ASSEMBLY *5 REAR SPEED SENSOR *6 REAR SUSPENS ...

Installation

Installation

INSTALLATION CAUTION / NOTICE / HINT HINT:

Use the same procedure for the RH side and LH side.

The following procedure is for the LH side.

PROCEDURE 1. INSTALL LOWER CONTROL ARM PIN (for TMMC ...

Other materials:

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Headlight Dimmer Switch: Inspection

INSPECTION PROCEDURE 1. INSPECT HEADLIGHT DIMMER SWITCH ASSEMBLY (a) Measure the resistance according to the value(s) in the table below. Standard Resistance: Light Control Switch Tester Connection Condition Specified Condition 18 (T) - 15 (EL) Light control switch in DRL OFF positi ...

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Headup Display System: Main Switch Circuit

DESCRIPTION The headup display switch assembly (integration control and panel assembly) and headup display (meter mirror sub-assembly) are connected via direct line. The headup display (meter mirror sub-assembly) can be turned off and on by operating the headup display switch assembly (integration c ...

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Owners Manual

- For your information

- Pictorial index

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Lexus Display Audio system

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Repair Manual

0.0109

.png)

.png)

.png)