Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual: Crankshaft Position Sensor

Components

COMPONENTS

ILLUSTRATION

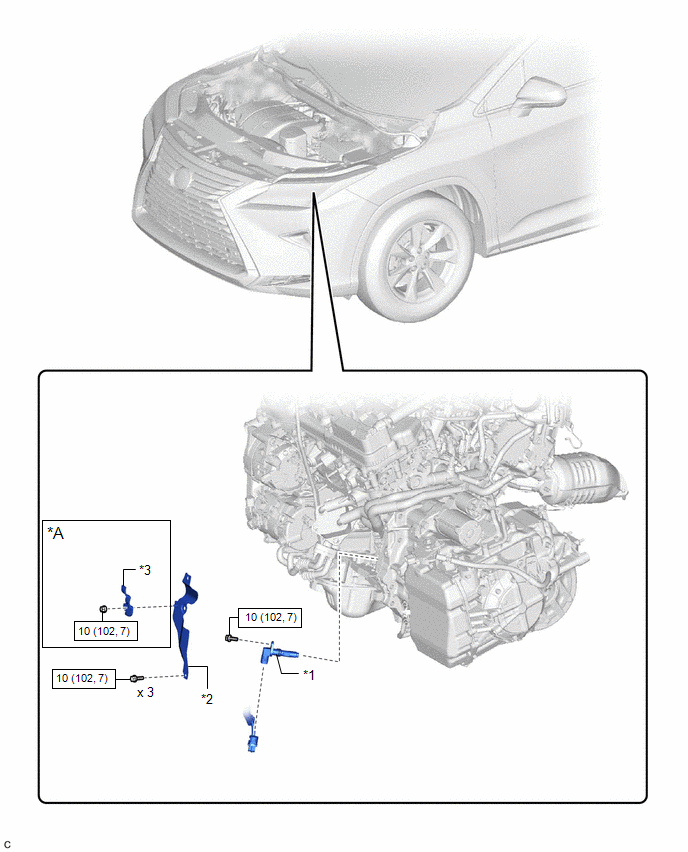

| *A | w/ Oil Cooler | - | - |

| *1 | CRANKSHAFT POSITION SENSOR | *2 | CRANKSHAFT POSITION SENSOR PROTECTOR |

| *3 | HOSE CLAMP | - | - |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | - | - |

Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during crankshaft position sensor removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

|---|---|---|---|

| Inspection After Repair |

| |

CAUTION:

-

To prevent burns, do not touch the engine, exhaust manifold or other high temperature components while the engine is hot.

.png)

-

To prevent burns, do not touch the engine, exhaust pipe or other high temperature components while the engine is hot.

.png)

PROCEDURE

1. REMOVE EXHAUST MANIFOLD SUB-ASSEMBLY LH (TWC: Front Catalyst)

Click here .gif)

2. REMOVE CRANKSHAFT POSITION SENSOR PROTECTOR

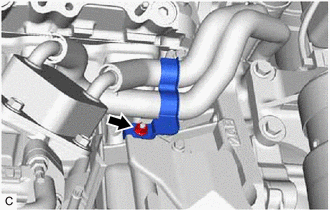

(a) w/ oil cooler:

| (1) Remove the nut and hose clamp from the crankshaft position sensor protector. |

|

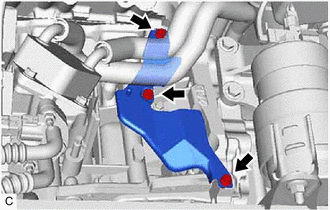

| (b) Remove the 3 bolts and crankshaft position sensor protector from the cylinder block sub-assembly and oil pan sub-assembly. |

|

3. REMOVE CRANKSHAFT POSITION SENSOR

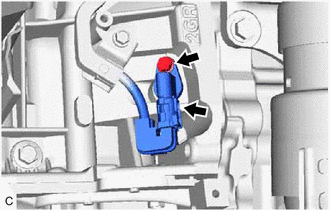

| (a) Disconnect the crankshaft position sensor connector. |

|

(b) Remove the bolt and crankshaft position sensor from the cylinder block sub-assembly.

NOTICE:

If the crankshaft position sensor has been struck or dropped, replace it.

Installation

INSTALLATION

PROCEDURE

1. INSTALL CRANKSHAFT POSITION SENSOR

(a) Apply a light coat of engine oil to the O-ring of the crankshaft position sensor.

NOTICE:

If reusing the crankshaft position sensor, be sure to inspect the O-ring.

(b) Install the crankshaft position sensor to the cylinder block sub-assembly with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

NOTICE:

- If the crankshaft position sensor has been struck or dropped, replace it.

- Make sure that the O-ring is not cracked or moved out of place when installing the crankshaft position sensor.

(c) Connect the crankshaft position sensor connector.

2. INSTALL CRANKSHAFT POSITION SENSOR PROTECTOR

(a) Install the crankshaft position sensor protector to the cylinder block sub-assembly and oil pan sub-assembly with the 3 bolts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(b) w/ oil cooler:

(1) Install the hose clamp to the crankshaft position sensor prtected with the nut.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

3. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY LH (TWC: Front Catalyst)

Click here .gif)

Installation

Installation

INSTALLATION PROCEDURE 1. INSTALL VVT SENSOR (for Exhaust Side of Bank 2) (a) Apply a light coat of engine oil to the O-ring of the VVT sensor. NOTICE: If reusing the VVT sensor, be sure to inspect th ...

Ecm

Ecm

...

Other materials:

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Wiper And Washer System: How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT HINT:

Use the following procedure to troubleshoot the wiper and washer system.

*: Use the Techstream.

PROCEDURE 1. VEHICLE BROUGHT TO WORKSHOP

NEXT 2. CUSTOMER PROBLEM ANALYSIS AND SYMPTOM CHECK

NEXT 3. INS ...

Lexus RX (RX 350L, RX450h) 2016-2026 Owners Manual > Driving procedures: Brake Hold

The brake hold system keeps the brake applied when the shift lever is

in D, S or

N with the system on and the brake pedal has been depressed to stop the vehicle.

The system releases the brake when the accelerator pedal is depressed

with the shift lever in D or S to allow smooth start off.

Tu ...

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Owners Manual

- For your information

- Pictorial index

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Lexus Display Audio system

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Repair Manual

0.0115