Lexus RX (RX 350L, RX450h) 2016-2025 Repair Manual: Crankshaft Position - Camshaft Position Correlation Bank 1 Sensor B (P001700,P001900)

DESCRIPTION

In the VVT (Variable Valve Timing) system, the appropriate exhaust valve open and close timing is controlled by the ECM. The ECM performs exhaust valve control by performing the following: 1) controlling the exhaust camshaft cam timing oil control solenoid assembly, camshaft timing gear bolt (camshaft timing oil control valve assembly [for exhaust camshaft]) and operating the camshaft timing exhaust gear; and 2) changing the relative positions of the camshaft and crankshaft.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | MIL | Memory | Note |

|---|---|---|---|---|---|---|

| P001700 | Crankshaft Position - Camshaft Position Correlation Bank 1 Sensor B | Deviation in the crankshaft position sensor signal and VVT sensor (for exhaust camshaft of bank 1) signal (2 trip detection logic). |

| Comes on | DTC stored | SAE Code: P0017 |

| P001900 | Crankshaft Position - Camshaft Position Correlation Bank 2 Sensor B | Deviation in the crankshaft position sensor signal and VVT sensor (for exhaust camshaft of bank 2) signal (2 trip detection logic). |

| Comes on | DTC stored | SAE Code: P0019 |

MONITOR DESCRIPTION

To monitor the correlation of the exhaust camshaft position and crankshaft position, the ECM checks the VVT learned value while the engine is idling. The VVT learned value is calibrated based on the camshaft position and crankshaft position. The exhaust valve timing is set to the neutral position while the engine is idling. If the VVT learned value is out of the specified range in consecutive driving cycles, the ECM stores a DTC.

MONITOR STRATEGY

| Related DTCs | P0017: Camshaft timing misalignment at idling (for exhaust camshaft of bank 1) P0019: Camshaft timing misalignment at idling (for exhaust camshaft of bank 2) |

| Required Sensors/Components (Main) | Camshaft timing exhaust gear assembly |

| Required Sensors/Components (Related) | VVT sensor Crankshaft position sensor |

| Frequency of Operation | Continuous |

| Duration | Within 1 minute |

| MIL Operation | 2 driving cycles |

| Sequence of Operation | None |

TYPICAL ENABLING CONDITIONS

| Monitor runs whenever the following DTCs are not stored | None |

| Engine speed | 500 to 1000 rpm |

TYPICAL MALFUNCTION THRESHOLDS

| Either of the following conditions is met | A or B |

| A. VVT learned value at maximum advanced valve timing | Less than 105.3°CA (Crankshaft Angle) |

| B. VVT learned value at maximum advanced valve timing | More than 130.4°CA (Crankshaft Angle) |

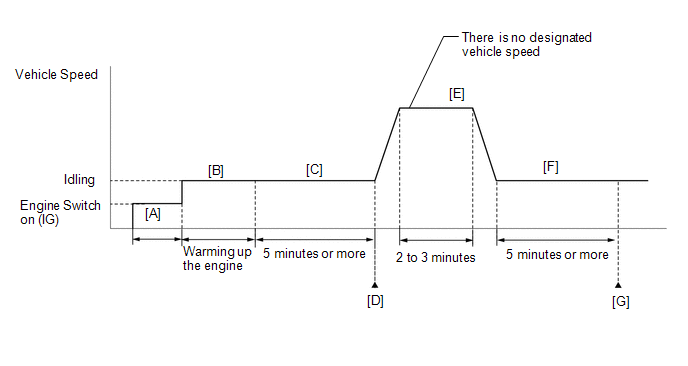

CONFIRMATION DRIVING PATTERN

HINT:

-

After repair has been completed, clear the DTC and then check that the vehicle has returned to normal by performing the following All Readiness check procedure.

Click here

.gif)

-

When clearing the permanent DTCs, refer to the "CLEAR PERMANENT DTC" procedure.

Click here

.gif)

- Connect the Techstream to the DLC3.

- Turn the engine switch on (IG).

- Turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the engine switch off and wait for at least 30 seconds.

- Turn the engine switch on (IG) [A].

- Turn the Techstream on.

- Start the engine and warm it up until the engine coolant temperature reaches 75°C (167°F) or higher [B].

- Idle the engine for 5 minutes or more [C].

- Enter the following menus: Powertrain / Engine / Trouble Codes [D].

-

Read the pending DTCs.

HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine / Utility / All Readiness.

- Input the DTC: P001700 or P001900.

-

Check the DTC judgment result.

Techstream Display

Description

NORMAL

- DTC judgment completed

- System normal

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

HINT:

- If the judgment result is NORMAL, the system is normal.

- If the judgment result is ABNORMAL, the system has a malfunction.

- If the judgment result is INCOMPLETE, perform steps [E] through [G].

-

[A] to [D]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- When clearing the permanent DTCs, do not disconnect the cable from the battery terminal or attempt to clear the DTCs during this procedure, as doing so will clear the universal trip and normal judgment histories.

-

Drive the vehicle for 2 to 3 minutes [E].

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

- Idle the engine for 5 minutes or more [F].

- Enter the following menus: Powertrain / Engine / Trouble Codes [G].

-

Read the pending DTCs.

HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

-

Check the DTC judgment result.

HINT:

- If the judgment result is NORMAL, the system is normal.

- If the judgment result is ABNORMAL, the system has a malfunction.

-

[A] to [G]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- When clearing the permanent DTCs, do not disconnect the cable from the battery terminal or attempt to clear the DTCs during this procedure, as doing so will clear the universal trip and normal judgment histories.

CAUTION / NOTICE / HINT

HINT:

-

Bank 1 refers to the bank that includes the No. 1 cylinder*.

*: The No. 1 cylinder is the cylinder which is farthest from the transaxle.

- Bank 2 refers to the bank that does not include the No. 1 cylinder.

- The monitor for this DTC detects when the timing chain is shifted by one tooth or more.

- Read freeze frame data using the Techstream. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

PROCEDURE

| 1. | CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P001700 OR P001900) |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine / Trouble Codes.

(e) Read the DTCs.

Powertrain > Engine > Trouble Codes| Result | Proceed to |

|---|---|

| DTC P001700 or P001900 is output | A |

| DTC P001700 or P001900 and other DTCs are output | B |

HINT:

If any DTCs other P001700 or P001900 are output, troubleshoot those DTCs first.

| B | .gif) | GO TO DTC CHART |

|

| 2. | PERFORM ACTIVE TEST USING TECHSTREAM (CONTROL THE EXHAUST VVT OCV DUTY RATIO) |

HINT:

If the VVT system can be operated through the Active Test, it can be assumed that the VVT system is operating normally.

(a) Connect the Techstream to the DLC3.

(b) Start the engine.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine / Active Test / Control the Exhaust VVT OCV Duty Ratio Bank 1 or Control the Exhaust VVT OCV Duty Ratio Bank 2 / Data List / Exhaust VVT Change Angle Bank 1 or Exhaust VVT Change Angle Bank 2.

Powertrain > Engine > Active Test| Active Test Display |

|---|

| Control the Exhaust VVT OCV Duty Ratio Bank 1 |

| Data List Display |

|---|

| Exhaust VVT Change Angle Bank 1 |

| Active Test Display |

|---|

| Control the Exhaust VVT OCV Duty Ratio Bank 2 |

| Data List Display |

|---|

| Exhaust VVT Change Angle Bank 2 |

(e) Perform the Active Test. Check that the displacement angle varies.

OK:

Displacement angle varies.

| NG | .gif) | GO TO STEP 4 |

|

| 3. | CHECK ENGINE MECHANICAL SYSTEM |

(a) Check for mechanical malfunctions that affect the valve timing, such as a jumped tooth or stretching of the timing chain.

| OK | .gif) | GO TO STEP 7 |

| NG | .gif) | REPAIR OR REPLACE MALFUNCTIONING PARTS, COMPONENT AND AREA |

| 4. | INSPECT CAM TIMING OIL CONTROL SOLENOID ASSEMBLY (FOR EXHAUST CAMSHAFT) |

(a) Inspect the cam timing oil control solenoid assembly (for exhaust camshaft).

-

for Bank 1: Click here

.gif)

-

for Bank 2: Click here

.gif)

| NG | .gif) | REPLACE CAM TIMING OIL CONTROL SOLENOID ASSEMBLY (FOR EXHAUST CAMSHAFT) |

|

| 5. | INSPECT CAMSHAFT TIMING GEAR BOLT (CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY [FOR EXHAUST CAMSHAFT]) |

(a) Inspect the camshaft timing gear bolt (camshaft timing oil control valve assembly [for exhaust camshaft]).

-

for Bank 1: Click here

.gif)

-

for Bank 2: Click here

.gif)

| NG | .gif) | REPLACE CAMSHAFT TIMING GEAR BOLT (CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY [FOR EXHAUST CAMSHAFT]) |

|

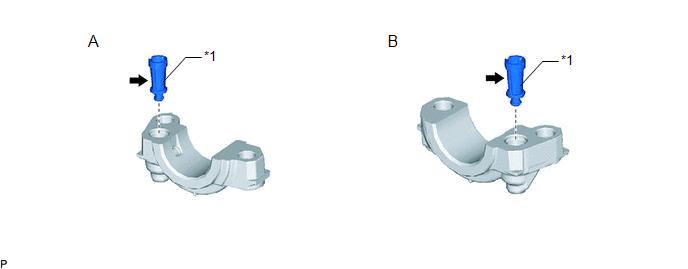

| 6. | INSPECT OIL CONTROL VALVE FILTER (FOR EXHAUST CAMSHAFT) |

| A | for Exhaust Camshaft of Bank 1 | B | for Exhaust Camshaft of Bank 2 |

| *1 | Oil Control Valve Filter | - | - |

(a) Remove the oil control valve filter (for exhaust camshaft of bank 1) or oil control valve filter (for exhaust camshaft of bank 2).

-

for Bank 1: Click here

.gif)

-

for Bank 2: Click here

.gif)

(b) Check that the filter is not clogged.

OK:

Filter is not clogged.

| NG | .gif) | REPLACE OIL CONTROL VALVE FILTER (FOR EXHAUST CAMSHAFT) |

|

| 7. | CHECK WHETHER DTC OUTPUT RECURS (DTC P001700 OR P001900) |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Clear the DTCs.

Powertrain > Engine > Clear DTCs(e) Turn the engine switch off and wait for at least 30 seconds.

(f) Turn the engine switch on (IG).

(g) Turn the Techstream on.

(h) Start the engine and warm it up.

(i) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(j) Enter the following menus: Powertrain / Engine / Trouble Codes / Pending.

(k) Read the pending DTCs.

Powertrain > Engine > Trouble Codes| Result | Proceed to |

|---|---|

| DTCs are not output | A |

| DTC P001700 or P001900 is output | B |

| A | .gif) | CHECK FOR INTERMITTENT PROBLEMS |

|

| 8. | REPLACE CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY |

(a) Replace the camshaft timing exhaust gear assembly.

Click here .gif)

.gif)

HINT:

Perform "Inspection After Repair" after replacing the camshaft timing exhaust gear assembly.

Click here .gif)

.gif)

|

| 9. | CHECK WHETHER DTC OUTPUT RECURS (DTC P001700 OR P001900) |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Clear the DTCs.

Powertrain > Engine > Clear DTCs(e) Turn the engine switch off and wait for at least 30 seconds.

(f) Turn the engine switch on (IG).

(g) Turn the Techstream on.

(h) Start the engine and warm it up.

(i) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(j) Enter the following menus: Powertrain / Engine / Trouble Codes / Pending.

(k) Read the pending DTCs.

Powertrain > Engine > Trouble Codes| Result | Proceed to |

|---|---|

| DTCs are not output | A |

| DTC P001700 or P001900 is output | B |

| A | .gif) | END |

| B | .gif) | REPLACE ECM |

Crankshaft Position - Camshaft Position Correlation Bank 1 Sensor A (P001600,P001800)

Crankshaft Position - Camshaft Position Correlation Bank 1 Sensor A (P001600,P001800)

DESCRIPTION In the VVT (Variable Valve Timing) system, the appropriate intake valve open and close timing is controlled by the ECM. The ECM performs intake valve control by performing the following: 1 ...

HO2S Heater Control Bank 1 Sensor 1 Circuit Short to Battery (P003012,P003013,P005012,P005013,P101A9E,P103A9E)

HO2S Heater Control Bank 1 Sensor 1 Circuit Short to Battery (P003012,P003013,P005012,P005013,P101A9E,P103A9E)

DESCRIPTION Refer to DTC P219519. Click here HINT:

When any of these DTCs are stored, the ECM enters fail-safe mode. The ECM turns off the air fuel ratio sensor heater in fail-safe mode. Fail-sa ...

Other materials:

Lexus RX (RX 350L, RX450h) 2016-2025 Repair Manual > Power Tilt And Power Telescopic Steering Column System: Data List / Active Test

DATA LIST / ACTIVE TEST READ DATA LIST HINT: Using the Techstream to read the Data List allows the values or states of switches, sensors, actuators and other items to be read without removing any parts. This non-intrusive inspection can be very useful because intermittent conditions or signals may b ...

Lexus RX (RX 350L, RX450h) 2016-2025 Repair Manual > Lighting System (w/o Automatic Headlight Beam Level Control System): Low Beam Headlight Circuit

DESCRIPTION The main body ECU (multiplex network body ECU) controls the low beam headlights. WIRING DIAGRAM CAUTION / NOTICE / HINT NOTICE:

Inspect the fuses for circuits related to this system before performing the following procedure.

Before replacing the main body ECU (multiplex network bod ...

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Owners Manual

- For your information

- Pictorial index

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Lexus Display Audio system

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Repair Manual

0.0173

.gif)