Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual: Components

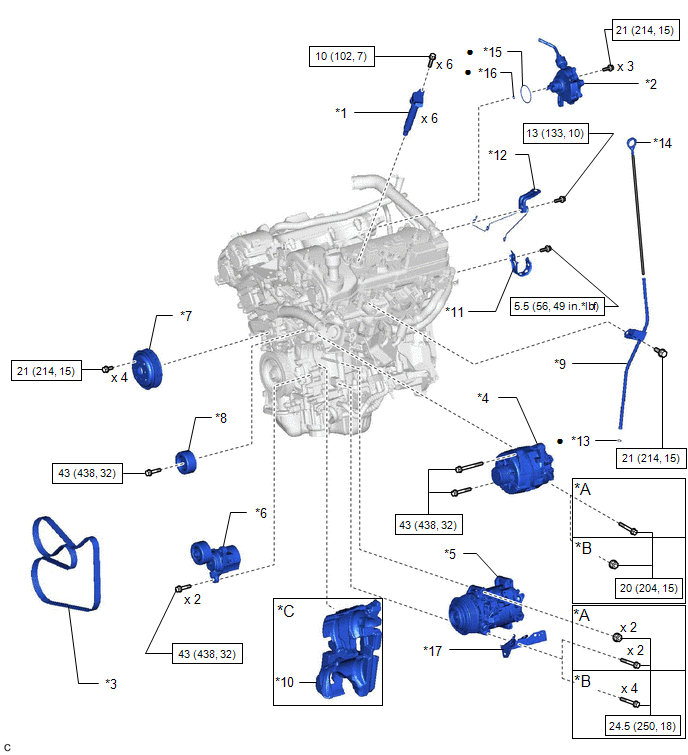

COMPONENTS

ILLUSTRATION

| *A | Type A | *B | Type B |

| *C | w/ Oil Cooler | - | - |

| *1 | IGNITION COIL ASSEMBLY | *2 | VACUUM PUMP ASSEMBLY |

| *3 | V-RIBBED BELT | *4 | GENERATOR ASSEMBLY |

| *5 | COMPRESSOR AND MAGNETIC CLUTCH | *6 | V-RIBBED BELT TENSIONER ASSEMBLY |

| *7 | WATER PUMP PULLEY | *8 | NO. 2 IDLER PULLEY SUB-ASSEMBLY |

| *9 | ENGINE OIL LEVEL DIPSTICK GUIDE | *10 | NO. 5 CYLINDER BLOCK INSULATOR |

| *11 | RADIATOR PIPE CLAMP | *12 | WIRE HARNESS CLAMP BRACKET |

| *13 | ENGINE OIL LEVEL DIPSTICK GUIDE O-RING | *14 | ENGINE OIL LEVEL DIPSTICK |

| *15 | NO. 2 O-RING | *16 | NO. 3 O-RING |

| *17 | BRACKET | - | - |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

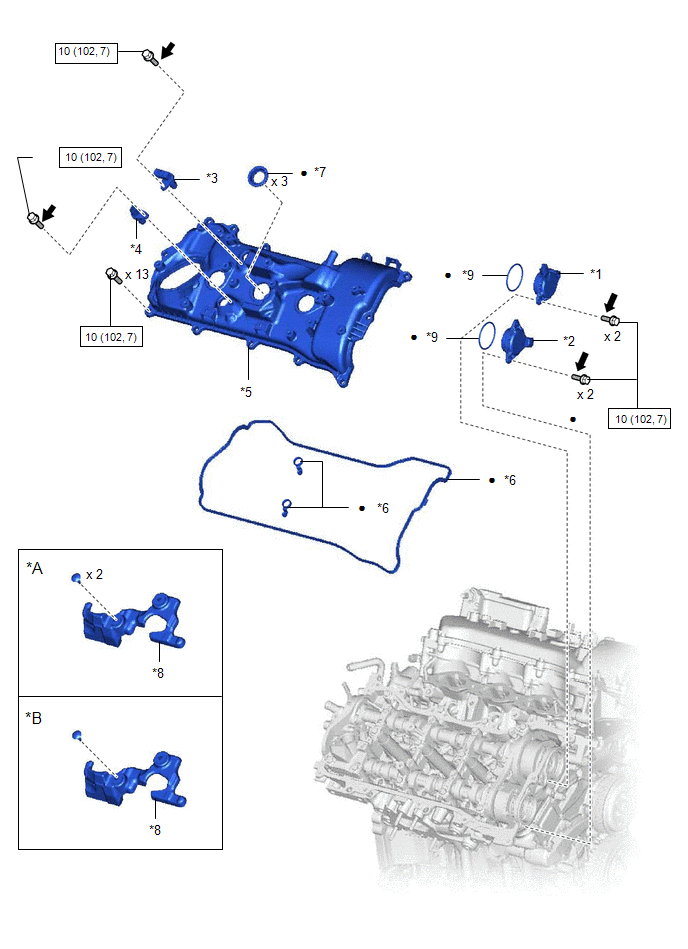

ILLUSTRATION

| *A | Type A | *B | Type B |

| *1 | CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY (for Intake Side of Bank 1) | *2 | CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY (for Exhaust Side of Bank 1) |

| *3 | VVT SENSOR (for Intake Side of Bank 1) | *4 | VVT SENSOR (for Exhaust Side of Bank 1) |

| *5 | CYLINDER HEAD COVER SUB-ASSEMBLY | *6 | CYLINDER HEAD COVER GASKET |

| *7 | SPARK PLUG TUBE GASKET | *8 | NO. 1 ENGINE COVER SUB-ASSEMBLY |

| *9 | O-RING | - | - |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

.png) | Adhesive 1324 | ★ | Precoated part |

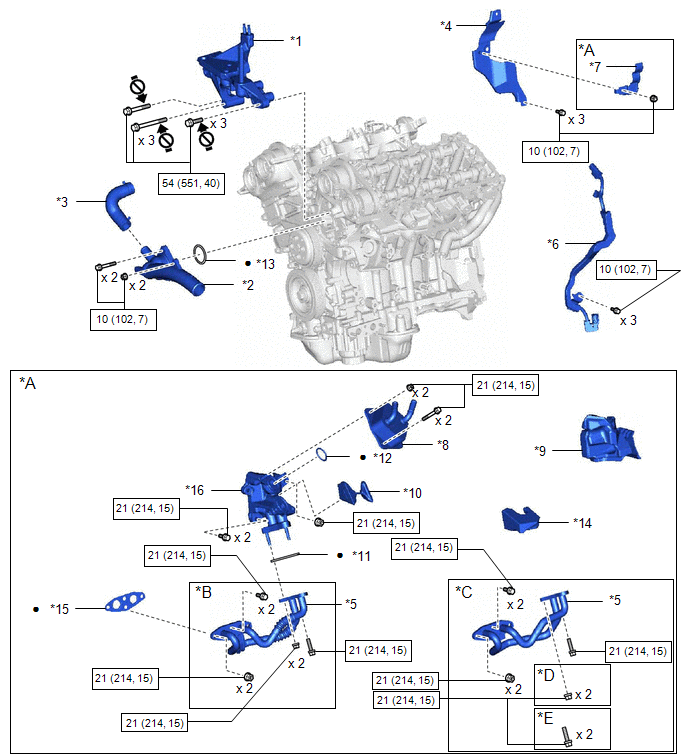

ILLUSTRATION

.png)

| *1 | CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY (for Intake Side of Bank 2) | *2 | CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY (for Exhaust Side of Bank 2) |

| *3 | VVT SENSOR (for Intake Side of Bank 2) | *4 | VVT SENSOR (for Exhaust Side of Bank 2) |

| *5 | CYLINDER HEAD COVER SUB-ASSEMBLY LH | *6 | NO. 2 CYLINDER HEAD COVER GASKET |

| *7 | SPARK PLUG TUBE GASKET | *8 | O-RING |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

.png) | Adhesive 1324 | ★ | Precoated part |

ILLUSTRATION

| *A | w/ Oil Cooler | *B | Type A |

| *C | Type B | *D | w/ Stud Bolt |

| *E | w/o Stud Bolt | - | - |

| *1 | FRONT NO. 1 ENGINE MOUNTING BRACKET LH | *2 | WATER INLET WITH THERMOSTAT SUB-ASSEMBLY |

| *3 | WATER BY-PASS HOSE | *4 | CRANKSHAFT POSITION SENSOR PROTECTOR |

| *5 | OIL COOLER PIPE | *6 | SENSOR WIRE |

| *7 | HOSE CLAMP | *8 | OIL COOLER ASSEMBLY |

| *9 | NO. 2 CYLINDER BLOCK INSULATOR | *10 | NO. 1 CYLINDER BLOCK INSULATOR |

| *11 | OIL COOLER GASKET | *12 | O-RING |

| *13 | GASKET | *14 | NO. 3 CYLINDER BLOCK INSULATOR |

| *15 | OIL HOLE COVER GASKET | *16 | NO. 1 OIL COOLER BRACKET |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

.png) | Do not apply lubricants to the threaded parts | - | - |

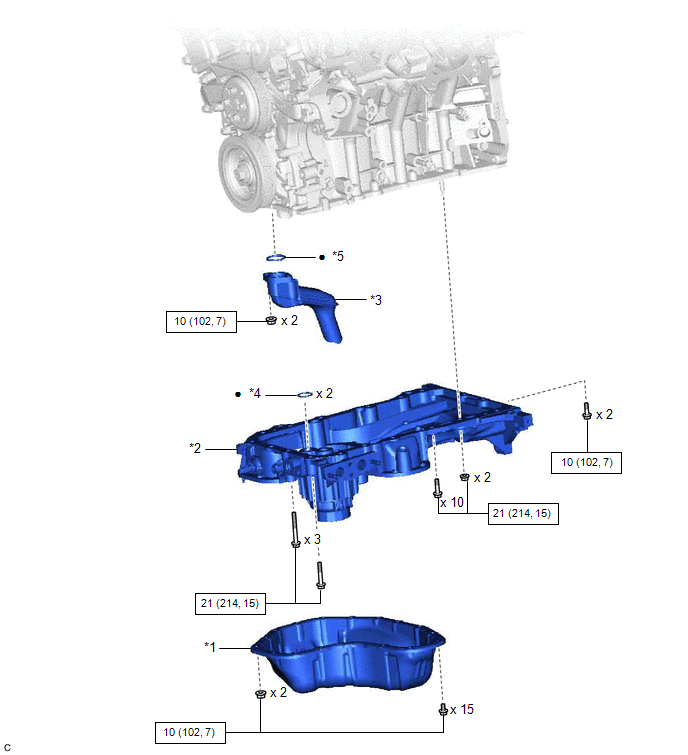

ILLUSTRATION

| *1 | NO. 2 OIL PAN SUB-ASSEMBLY | *2 | OIL PAN SUB-ASSEMBLY |

| *3 | OIL STRAINER SUB-ASSEMBLY | *4 | OIL PAN GASKET |

| *5 | OIL STRAINER GASKET | - | - |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

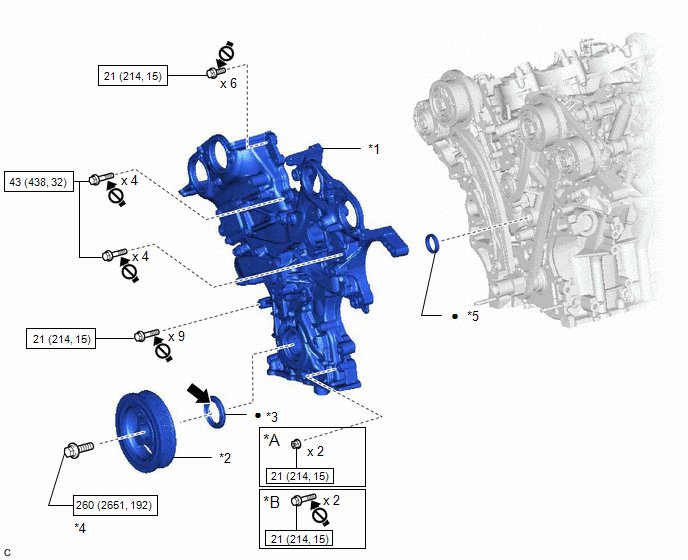

ILLUSTRATION

| *A | w/ Stud Bolt | *B | w/o Stud Bolt |

| *1 | TIMING CHAIN COVER ASSEMBLY | *2 | CRANKSHAFT PULLEY |

| *3 | TIMING CHAIN CASE OIL SEAL | *4 | CRANKSHAFT PULLEY SET BOLT |

| *5 | OIL PUMP GASKET | - | - |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

.png) | MP grease | .png) | Do not apply lubricants to the threaded parts |

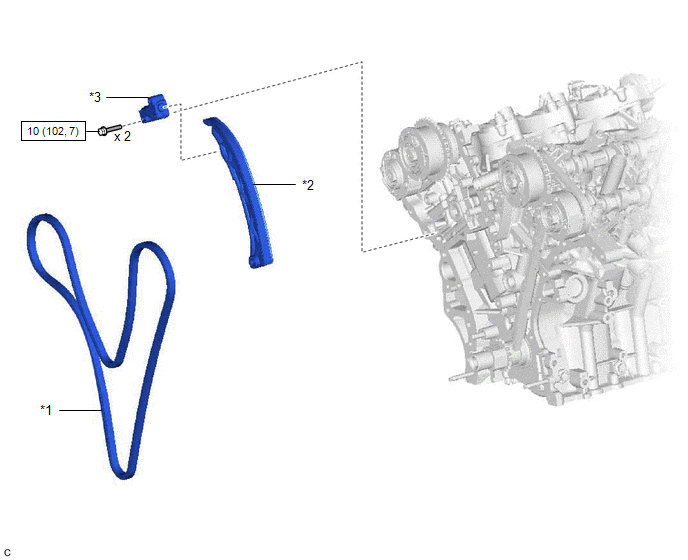

ILLUSTRATION

| *1 | CHAIN SUB-ASSEMBLY | *2 | CHAIN TENSIONER SLIPPER |

| *3 | NO. 1 CHAIN TENSIONER ASSEMBLY | - | - |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | - | - |

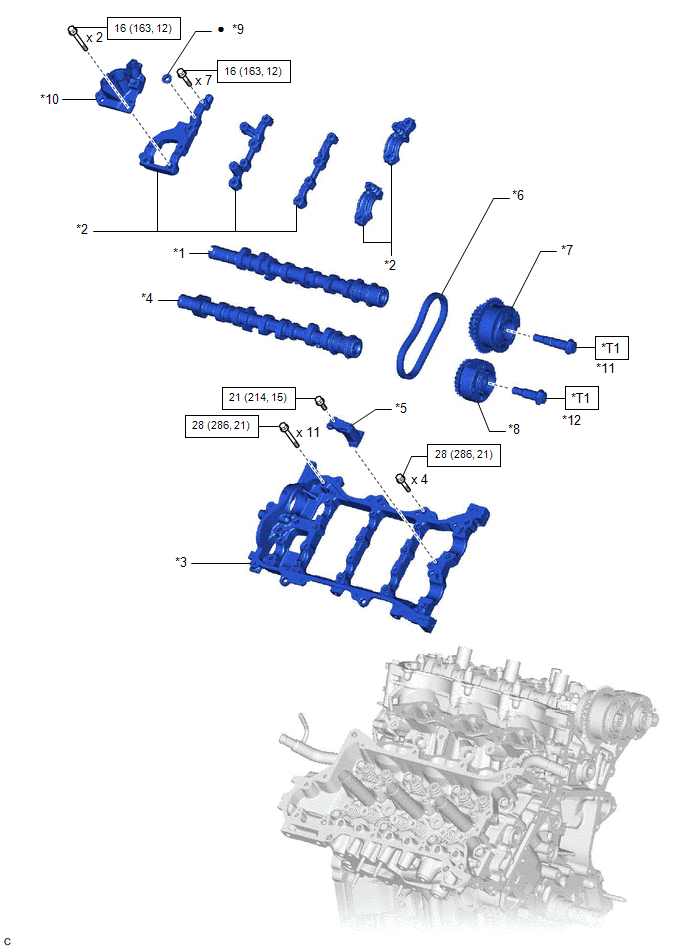

ILLUSTRATION

| *1 | CAMSHAFT | *2 | CAMSHAFT BEARING CAP (for Bank 1) |

| *3 | CAMSHAFT HOUSING SUB-ASSEMBLY | *4 | NO. 2 CAMSHAFT |

| *5 | NO. 2 CHAIN TENSIONER ASSEMBLY | *6 | NO. 2 CHAIN SUB-ASSEMBLY (for Bank 1) |

| *7 | CAMSHAFT TIMING GEAR ASSEMBLY (for Bank 1) | *8 | CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY (for Bank 1) |

| *9 | CAMSHAFT BEARING CAP OIL HOLE GASKET | *10 | FUEL PUMP LIFTER HOUSING |

| *11 | CAMSHAFT TIMING GEAR BOLT (for Intake Side of Bank 1) | *12 | CAMSHAFT TIMING GEAR BOLT (for Exhaust Side of Bank 1) |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

| *T1 | Type A: 120 N*m (1224 kgf*cm, 89 ft.*lbf) Type B: 95 N*m (969 kgf*cm, 70 ft.*lbf) | - | - |

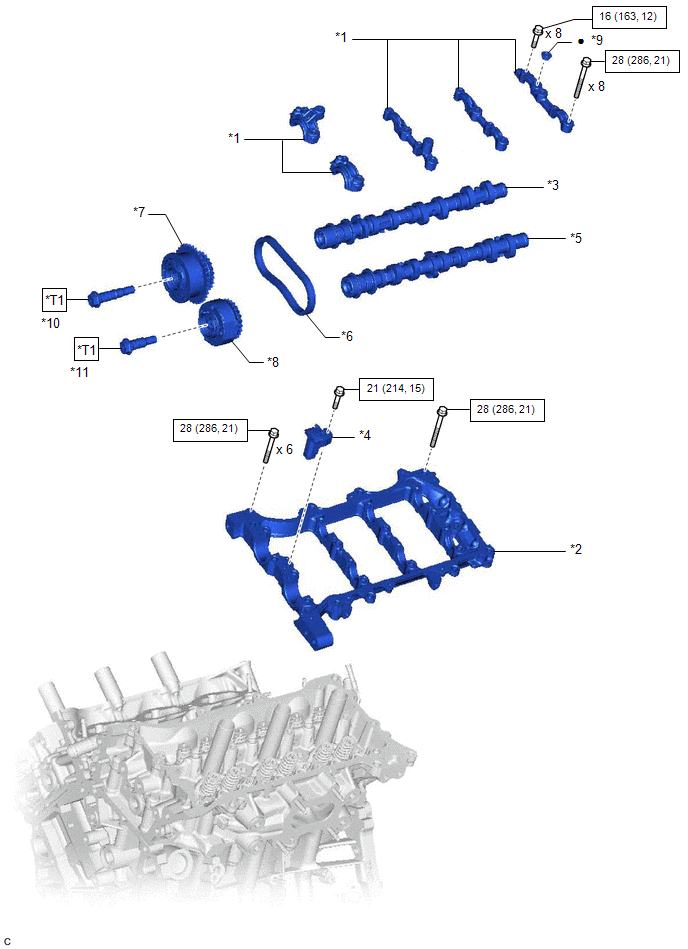

ILLUSTRATION

| *1 | CAMSHAFT BEARING CAP (for Bank 2) | *2 | CAMSHAFT HOUSING SUB-ASSEMBLY LH |

| *3 | NO. 3 CAMSHAFT SUB-ASSEMBLY | *4 | NO. 3 CHAIN TENSIONER ASSEMBLY |

| *5 | NO. 4 CAMSHAFT SUB-ASSEMBLY | *6 | NO. 2 CHAIN SUB-ASSEMBLY (for Bank 2) |

| *7 | CAMSHAFT TIMING GEAR ASSEMBLY (for Bank 2) | *8 | CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY (for Bank 2) |

| *9 | CAMSHAFT BEARING CAP OIL HOLE GASKET | *10 | CAMSHAFT TIMING GEAR BOLT (for Intake Side of Bank 2) |

| *11 | CAMSHAFT TIMING GEAR BOLT (for Exhaust Side of Bank 2) | - | - |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

| *T1 | Type A: 120 N*m (1224 kgf*cm, 89 ft.*lbf) Type B: 95 N*m (969 kgf*cm, 70 ft.*lbf) | - | - |

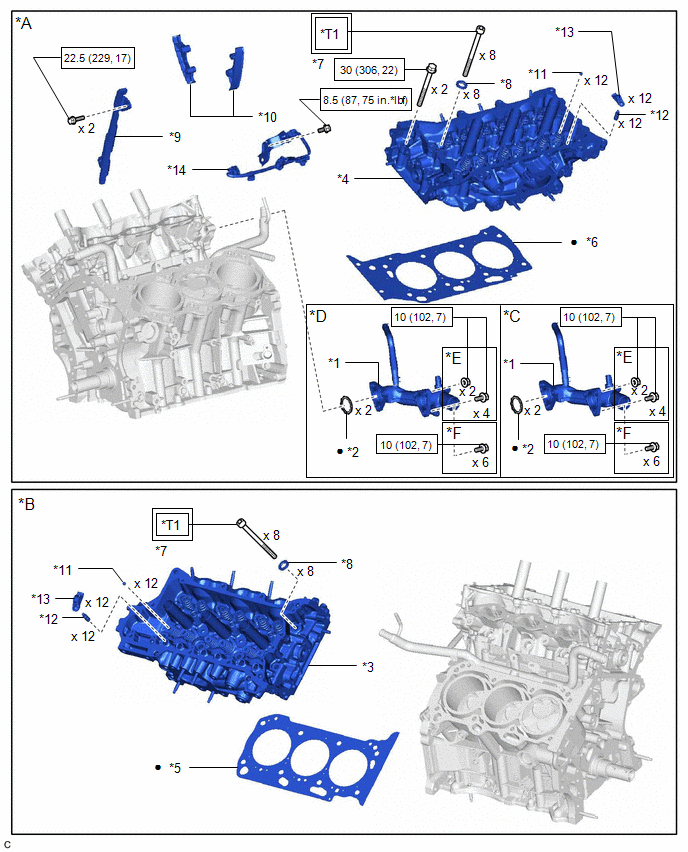

ILLUSTRATION

| *A | for Bank 2 | *B | for Bank 1 |

| *C | w/o Oil Cooler | *D | w/ Oil Cooler |

| *E | w/ Stud Bolt | *F | w/o Stud Bolt |

| *1 | WATER OUTLET | *2 | NO. 2 WATER INLET HOUSING GASKET |

| *3 | CYLINDER HEAD SUB-ASSEMBLY | *4 | CYLINDER HEAD LH |

| *5 | CYLINDER HEAD GASKET | *6 | NO. 2 CYLINDER HEAD GASKET |

| *7 | CYLINDER HEAD SET BOLT | *8 | CYLINDER HEAD SET PLATE WASHER |

| *9 | NO. 1 CHAIN VIBRATION DAMPER | *10 | NO. 2 CHAIN VIBRATION DAMPER |

| *11 | VALVE STEM CAP | *12 | VALVE LASH ADJUSTER ASSEMBLY |

| *13 | NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY | *14 | SENSOR WIRE |

.png) | Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) | .png) | N*m (kgf*cm, ft.*lbf): Specified torque |

| ● | Non-reusable part | - | - |

| *T1 | 1st: 36 (367, 27) 2nd: Turn 90° 3rd: Turn 90° | - | - |

Removal

Removal

REMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during eng ...

Other materials:

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Occupant Classification System: Precaution

PRECAUTION PRECAUTION FOR DISCONNECTING CABLE FROM NEGATIVE BATTERY TERMINAL NOTICE: When disconnecting the cable from the negative (-) battery terminal, initialize the following systems after the cable is reconnected: System See Procedure Lane Control System Pre-collision System ...

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Wireless Door Lock Control System: Terminals Of Ecu

TERMINALS OF ECU CHECK INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY AND MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) (a) Remove the main body ECU (multiplex network body ECU) from the instrument panel junction block assembly. (b) Reconnect the instrument panel junction block assembly connector. (c) Measu ...

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Owners Manual

- For your information

- Pictorial index

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Lexus Display Audio system

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Repair Manual

0.0088