Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual: Installation

INSTALLATION

PROCEDURE

1. INSTALL STUD BOLT

NOTICE:

If a stud bolt is deformed or its threads are damaged, replace it.

| (a) Using an 8 mm socket wrench, install the stud bolt to the front No. 1 engine mounting bracket LH. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} |

|

2. INSTALL RADIATOR PIPE CLAMP

(a) Install the radiator pipe clamp to the camshaft housing sub-assembly LH with the bolt.

Torque:

5.5 N·m {56 kgf·cm, 49 in·lbf}

3. INSTALL WIRE HARNESS CLAMP BRACKET

(a) Install the wire harness clamp bracket to the camshaft housing sub-assembly with the bolt.

Torque:

13 N·m {133 kgf·cm, 10 ft·lbf}

4. INSTALL NO. 1 EXHAUST PIPE SUPPORT BRACKET

(a) Install the No. 1 exhaust pipe support bracket to the oil pan sub-assembly with the 2 bolts.

Torque:

21 N·m {214 kgf·cm, 15 ft·lbf}

5. INSTALL DRIVE SHAFT BEARING BRACKET (for 2WD)

(a) Install the drive shaft bearing bracket to the cylinder block sub-assembly with the 3 bolts.

Torque:

63.7 N·m {650 kgf·cm, 47 ft·lbf}

NOTICE:

Make sure that there is no oil on the threads of the bolts.

6. INSTALL NO. 2 TRANSFER STIFFENER PLATE (for AWD)

(a) Install the No. 2 transfer stiffener plate to the cylinder block sub-assembly with the 3 bolts.

Torque:

64 N·m {653 kgf·cm, 47 ft·lbf}

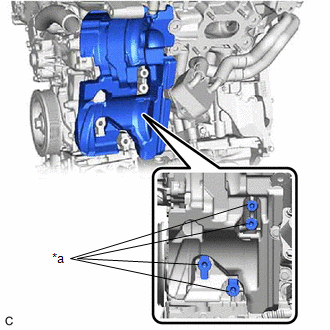

7. INSTALL NO. 5 CYLINDER BLOCK INSULATOR (w/ Oil Cooler)

| (a) Install the No. 5 cylinder block insulator to the engine assembly. NOTICE: Make sure that the No. 5 cylinder block insulator is not covering any fastener surface. |

|

8. INSTALL ENGINE OIL LEVEL DIPSTICK GUIDE

(a) Install a new engine oil level dipstick guide O-ring to the engine oil level dipstick guide.

(b) Apply a light coat of engine oil to the engine oil level dipstick guide O-ring.

(c) Insert the engine oil level dipstick guide end into the oil pan sub-assembly.

(d) Install the engine oil level dipstick guide to the camshaft housing sub-assembly LH with the bolt.

Torque:

21 N·m {214 kgf·cm, 15 ft·lbf}

(e) Install the engine oil level dipstick to the engine oil level dipstick guide.

9. INSTALL WATER PUMP PULLEY

Click here .gif)

10. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY

(a) Install the V-ribbed belt tensioner assembly with the 2 bolts.

Torque:

43 N·m {438 kgf·cm, 32 ft·lbf}

11. INSTALL NO. 2 IDLER PULLEY SUB-ASSEMBLY

Click here .gif)

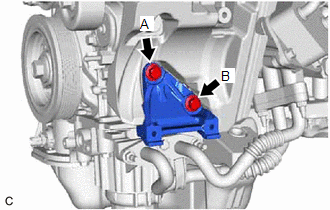

12. INSTALL NO. 1 COMPRESSOR MOUNTING BRACKET

| (a) Install the No. 1 compressor mounting bracket to the cylinder block sub-assembly with the 2 bolts. Torque: 43 N·m {438 kgf·cm, 32 ft·lbf} NOTICE: Temporarily tighten the bolt (A), and then fully tighten the 2 bolts in the order of (B) and (A). |

|

13. INSTALL COMPRESSOR AND MAGNETIC CLUTCH

Click here .gif)

.gif)

14. INSTALL GENERATOR ASSEMBLY

-

for 180A Type:

Click here

.gif)

-

for 150A Type:

Click here

.gif)

15. INSTALL V-RIBBED BELT

Click here .gif)

16. INSTALL NO. 2 VENTILATION HOSE

(a) Install the No. 2 ventilation hose to the cylinder head cover sub-assembly and slide the clip to secure it.

17. INSTALL VENTILATION HOSE

(a) Install the ventilation hose to the PCV valve (ventilation valve sub-assembly) and slide the clip to secure it.

18. INSTALL NO. 2 WATER BY-PASS HOSE

(a) Install the No. 2 water by-pass hose to the water outlet and slide the clip to secure it.

19. INSTALL NO. 3 WATER BY-PASS HOSE

(a) Install the No. 3 water by-pass hose to the water inlet pipe and slide the clip to secure it.

20. INSTALL VACUUM PUMP ASSEMBLY

Click here .gif)

21. INSTALL IGNITION COIL ASSEMBLY

Click here .gif)

22. INSTALL SENSOR WIRE

(a) Engage the 2 clamps and install the sensor wire to the water inlet pipe with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

23. INSTALL KNOCK CONTROL SENSOR

Click here .gif)

Disassembly

Disassembly

DISASSEMBLY PROCEDURE 1. REMOVE OIL FILLER CAP SUB-ASSEMBLY (a) Remove the oil filler cap sub-assembly from the cylinder head cover sub-assembly LH. (b) Remove the oil filler cap gas ...

Reassembly

Reassembly

REASSEMBLY PROCEDURE 1. INSTALL WATER INLET PIPE (a) Install the water inlet pipe with the 2 bolts. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} *A w/o Oil Cooler *B w/ Oil Cooler ...

Other materials:

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Seat Heater System: Problem Symptoms Table

PROBLEM SYMPTOMS TABLE NOTICE:

If the battery voltage is low, the seat heater system may not operate. When "Operation of Electrical Items Restricted." is displayed on the multi-information display in the combination meter assembly, inspect the battery, referring to On-vehicle Inspection for the c ...

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Air Conditioning System: Evaporator Temperature Circuit (B1417/17)

DESCRIPTION The No. 2 air conditioning harness assembly is installed on the evaporator in the rear air conditioner unit to detect the temperature of the cooled air that has passed through the evaporator, which is used to control the air conditioning system. It sends signals to the air conditioning a ...

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Owners Manual

- For your information

- Pictorial index

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Lexus Display Audio system

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Repair Manual

0.0103

.png)