Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual: Left Front Wheel Speed Sensor Circuit Short to Battery (C050012)

DESCRIPTION

Refer to DTC C05001F.

Click here .gif)

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area |

|---|---|---|---|

| C050012 | Left Front Wheel Speed Sensor Circuit Short to Battery | The speed sensor short signal is ON continuously for 0.5 seconds or more. |

|

*: w/ AVS

WIRING DIAGRAM

Click here .gif)

CAUTION / NOTICE / HINT

NOTICE:

-

After replacing the skid control ECU (brake actuator assembly), perform "Calibration".

Click here

.gif)

-

After replacing or removing and installing a speed sensor, perform Dealer Mode (Signal Check) inspection to confirm that the speed sensors are operating correctly.

Click here

.gif)

PROCEDURE

| 1. | CHECK VEHICLE SPECIFICATION |

(a) Check the vehicle specification.

| Result | Proceed to |

|---|---|

| w/o AVS | A |

| w/ AVS | B |

| B | .gif) | GO TO STEP 5 |

|

| 2. | CHECK HARNESS AND CONNECTOR (SENSOR GROUND CIRCUIT) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

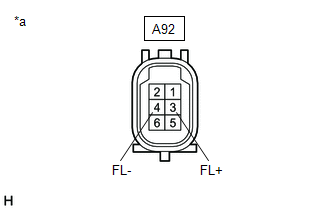

(b) Disconnect the A92 front speed sensor LH connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Turn the engine switch on (IG).

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A92-3 (FL+) - A92-4 (FL-) | Engine switch on (IG) | 11 to 14 V |

| OK | .gif) | REPLACE FRONT SPEED SENSOR LH |

|

| 3. | CHECK HARNESS AND CONNECTOR (SENSOR GROUND CIRCUIT) |

| (a) Turn the engine switch off. |

|

(b) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

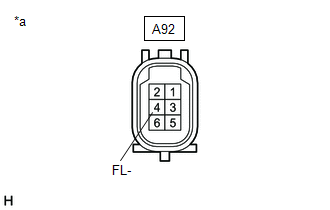

(c) Disconnect the A41 skid control ECU (brake actuator assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A92-4 (FL-) - Body ground | Always | Below 1.5 V |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 4. | CHECK HARNESS AND CONNECTOR (FRONT SPEED SENSOR LH - BRAKE ACTUATOR ASSEMBLY) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A92-3 (FL+) or A41-22 (FL+) - A92-4 (FL-) or A41-21 (FL-) | Always | 10 kΩ or higher |

| OK | .gif) | REPLACE BRAKE ACTUATOR ASSEMBLY |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 5. | CHECK HARNESS AND CONNECTOR (SENSOR GROUND CIRCUIT) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

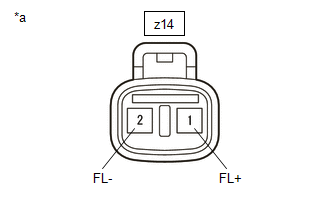

(b) Disconnect the z14 front speed sensor LH connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Turn the engine switch on (IG).

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| z14-1 (FL+) - z14-2 (FL-) | Engine switch on (IG) | 11 to 14 V |

| OK | .gif) | REPLACE FRONT SPEED SENSOR LH |

|

| 6. | CHECK HARNESS AND CONNECTOR (SENSOR GROUND CIRCUIT) |

| (a) Turn the engine switch off. |

|

(b) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

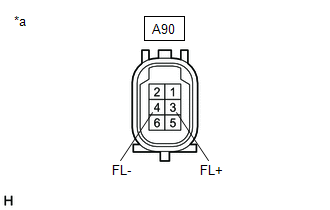

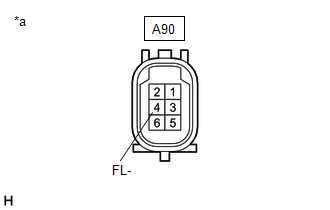

(c) Disconnect the A90 front skid control sensor wire LH connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Turn the engine switch on (IG).

(f) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A90-3 (FL+) - A90-4 (FL-) | Engine switch on (IG) | 11 to 14 V |

| OK | .gif) | REPLACE FRONT SKID CONTROL SENSOR WIRE LH |

|

| 7. | CHECK HARNESS AND CONNECTOR (SENSOR GROUND CIRCUIT) |

| (a) Turn the engine switch off. |

|

(b) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(c) Disconnect the A41 skid control ECU (brake actuator assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A90-4 (FL-) - Body ground | Always | Below 1.5 V |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 8. | CHECK HARNESS AND CONNECTOR (FRONT SKID CONTROL SENSOR WIRE LH - BRAKE ACTUATOR ASSEMBLY) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A90-3 (FL+) or A41-22 (FL+) - A90-4 (FL-) or A41-21 (FL-) | Always | 10 kΩ or higher |

| OK | .gif) | REPLACE BRAKE ACTUATOR ASSEMBLY |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

Yaw Rate Sensor Signal Stuck In Range (C00632A,C05201C,C05202A,C052096)

Yaw Rate Sensor Signal Stuck In Range (C00632A,C05201C,C05202A,C052096)

DESCRIPTION for Optitron Meter Type:

The airbag sensor assembly has a built-in yaw rate and acceleration sensor and detects the vehicle condition.

These DTCs are stored when the skid control ECU (b ...

Left Front Wheel Speed Sensor Circuit Short to Ground or Open (C050014)

Left Front Wheel Speed Sensor Circuit Short to Ground or Open (C050014)

DESCRIPTION Refer to DTC C05001F. Click here DTC No. Detection Item DTC Detection Condition Trouble Area C050014 Left Front Wheel Speed Sensor Circuit Short to Ground or Open An ope ...

Other materials:

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Power Seat Switch(w/o Seat Position Memory System): Inspection

INSPECTION PROCEDURE 1. INSPECT FRONT POWER SEAT SWITCH LH (a) Measure the resistance according to the value(s) in the table below. Standard Resistance: Slide Switch Tester Connection Condition Specified Condition 5 - 7 Slide switch pressed (Front) Below 1 Ω 5 - 8 2 - 11 ...

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Rear Brake: Components

COMPONENTS ILLUSTRATION *1 NO. 2 PARKING BRAKE WIRE ASSEMBLY *2 PARKING BRAKE ACTUATOR ASSEMBLY *3 O-RING - - N*m (kgf*cm, ft.*lbf): Specified torque ● Non-reusable part Lithium soap base glycol grease - - ILLUSTRATION *1 REAR DISC BRAKE CYLINDER ...

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Owners Manual

- For your information

- Pictorial index

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Lexus Display Audio system

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Repair Manual

0.009

.gif)