Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual: Right Electric Parking Brake Actuator Circuit Current Above Threshold (C061319)

DESCRIPTION

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | Memory | Note |

|---|---|---|---|---|---|

| C061319 | Right Electric Parking Brake Actuator Circuit Current Above Threshold | When the electric parking brake is operating, overcurrent is detected in the parking brake actuator assembly RH 3 times |

| DTC stored | An electric parking brake system malfunction is displayed on the multi-information display. |

WIRING DIAGRAM

Click here .gif)

CAUTION / NOTICE / HINT

NOTICE:

- The electric parking brake may still operate up to 20 seconds after the engine switch is turned off. Before disconnecting connectors or fuses, turn the engine switch off and wait 20 seconds or more.

-

After replacing the skid control ECU (brake actuator assembly), perform "Calibration".

Click here

.gif)

- When replacing the skid control ECU (brake actuator assembly), operate the electric parking brake switch (electric parking brake switch assembly) as the parking brake indicator light blinks (red) when the engine switch is first turned on (IG).

PROCEDURE

| 1. | INSPECT NO. 1 PARKING BRAKE WIRE ASSEMBLY |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

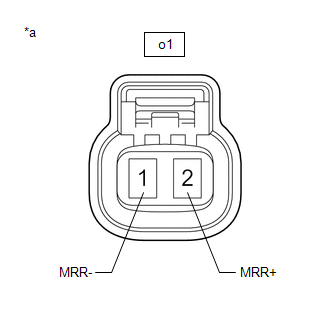

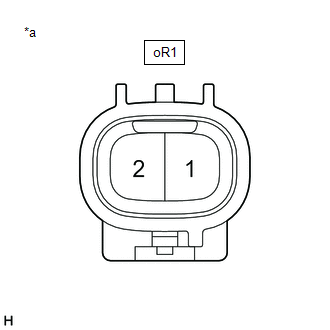

(b) Disconnect the oR1 and o1 No. 1 parking brake wire assembly connectors.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the resistance according to the value(s) in the table below.

.png)

| *a | Front view of No. 1 Parking Brake Wire Assembly | *b | (to wire harness connector) |

| *c | (to Parking Brake Actuator Assembly RH) | - | - |

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| oR1-1 - o1-2 (MRR+) | Always | Below 1 Ω |

| oR1-1 or o1-2 (MRR+) - Body ground and other terminals | Always | 10 kΩ or higher |

| oR1-2 - o1-1 (MRR-) | Always | Below 1 Ω |

| oR1-2 or o1-1 (MRR-) - Body ground and other terminals | Always | 10 kΩ or higher |

| NG | .gif) | REPLACE NO. 1 PARKING BRAKE WIRE ASSEMBLY |

|

| 2. | CHECK HARNESS AND CONNECTOR (SKID CONTROL ECU (BRAKE ACTUATOR ASSEMBLY) - PARKING BRAKE ACTUATOR ASSEMBLY RH) |

(a) Make sure the No. 1 parking brake wire assembly is securely installed.

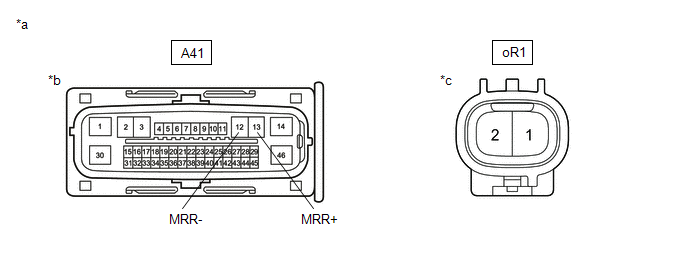

(b) Disconnect the A41 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the o1 parking brake actuator assembly RH connector.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A41-13 (MRR+) - o1-2 (MRR+) | Always | Below 1 Ω |

| A41-13 (MRR+) or o1-2 (MRR+) - Body ground | Always | 10 kΩ or higher |

| A41-12 (MRR-) - o1-1 (MRR-) | Always | Below 1 Ω |

| A41-12 (MRR-) or o1-1 (MRR-) - Body ground | Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 3. | INSPECT PARKING BRAKE ACTUATOR ASSEMBLY RH |

(a) Remove the parking brake actuator assembly RH.

Click here .gif)

(b) Inspect the parking brake actuator assembly RH.

Click here .gif)

| NG | .gif) | REPLACE PARKING BRAKE ACTUATOR ASSEMBLY RH |

|

| 4. | CHECK FOR SHORT TO +B |

(a) Turn the engine switch off.

(b) Make sure the No. 1 parking brake wire assembly is securely installed.

(c) Disconnect the o1 parking brake actuator assembly RH connector.

| (d) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| OK | .gif) | REPLACE PARKING BRAKE ACTUATOR ASSEMBLY RH |

|

| 5. | CHECK FOR SHORT TO +B |

(a) Disconnect the oR1 No. 1 parking brake wire assembly connector.

| (b) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| OK | .gif) | REPLACE NO. 1 PARKING BRAKE WIRE ASSEMBLY |

|

| 6. | CHECK FOR SHORT TO +B |

(a) Disconnect the oR1 No. 1 parking brake wire assembly connector.

(b) Disconnect the A41 skid control ECU (brake actuator assembly) connector.

(c) Measure the voltage according to the value(s) in the table below.

| *a | Front view of wire harness connector | *b | (to Skid Control ECU (Brake Actuator Assembly)) |

| *c | (to No. 1 Parking Brake Wire Assembly) | - | - |

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| oR1-1 or A41-13 (MRR+) - Body ground | Always | Below 1 V |

| oR1-2 or A41-12 (MRR-) - Body ground | Always | Below 1 V |

| OK | .gif) | REPLACE SKID CONTROL ECU (BRAKE ACTUATOR ASSEMBLY) |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

Right Electric Parking Brake Actuator Control Circuit Short to Ground or Open (C061014)

Right Electric Parking Brake Actuator Control Circuit Short to Ground or Open (C061014)

DESCRIPTION DTC No. Detection Item DTC Detection Condition Trouble Area Memory Note C061014 Right Electric Parking Brake Actuator Control Circuit Short to Ground or Open

Diagno ...

Right Electric Parking Brake Actuator Signal Stuck In Range (C06132A)

Right Electric Parking Brake Actuator Signal Stuck In Range (C06132A)

DESCRIPTION DTC No. Detection Item DTC Detection Condition Trouble Area Memory Note C06132A Right Electric Parking Brake Actuator Signal Stuck In Range

Diagnosis Condition:

Ele ...

Other materials:

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Yaw Rate And Acceleration Sensor: Components

COMPONENTS ILLUSTRATION *1 FRONT NO. 2 CONSOLE BOX INSERT - - ILLUSTRATION *1 YAW RATE SENSOR ASSEMBLY *2 CONNECTOR N*m (kgf*cm, ft.*lbf): Specified torque - - ...

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Rear Differential Carrier Assembly: Reassembly

REASSEMBLY CAUTION / NOTICE / HINT NOTICE:

Before installation, thoroughly clean and dry each part and then apply Toyota Genuine Differential gear oil LT SAE 75W-85 GL-5 or equivalent to them.

Do not use alkaline cleaner for aluminum or rubber parts and rear differential case bolts.

Do not cl ...

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Owners Manual

- For your information

- Pictorial index

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Lexus Display Audio system

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Repair Manual

0.0118

.gif)