Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual: Shift Solenoid "B" Circuit Short to Battery or Open (P075515)

DESCRIPTION

Changing gears is performed by the ECM turning the shift solenoid valves SL1, SL2, SL3, SL4, SL5, S1 and S2 on and off.

If an open or short occurs in any of the shift solenoid valve circuits, the ECM controls the remaining normal shift solenoid valves to allow the vehicle to be driven. If all of the shift solenoid valves are malfunctioning, only the mechanical fluid pressure circuit will function and some manual operation will be possible. If an open or short occurs in a shift solenoid valve circuit, the ECM cuts power to the malfunctioning shift solenoid valve.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | MIL | Memory | Note |

|---|---|---|---|---|---|---|

| P075515 | Shift Solenoid "B" Circuit Short to Battery or Open | 1. Diagnosis Condition 2. Malfunction Status 3. Malfunction Time 4. Other

|

| Does not come on | DTC stored | SAE Code: P0977 |

MONITOR DESCRIPTION

This DTC indicates an open or short to +B in the shift solenoid valve S2 circuit. When there is an open or short in any shift solenoid valve circuit, the ECM detects the problem, illuminates the MIL and stores a DTC.

When the shift solenoid valve S2 is off, if its resistance is 100 kΩ or more, the ECM determines there is an open or short to +B in the shift solenoid valve S2 circuit.

CONFIRMATION DRIVING PATTERN

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

HINT:

After repairs have been completed, clear the DTCs and then check that the vehicle has returned to normal by performing the following All Readiness check procedure.

- Connect the Techstream to the DLC3.

- Turn the engine switch on (IG) and turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the engine switch off and wait for 2 minutes or more.

- Turn the engine switch on (IG) and turn the Techstream on.

- Start the engine.

-

Perform the D Position Shift Test inspection in Road Test.

Click here

.gif)

.gif)

- Enter the following menus: Powertrain / Transmission / Utility / All Readiness.

- Input the DTC: P075515.

-

Check the DTC judgment result.

Techstream Display

Description

NORMAL

- DTC judgment completed

- System normal

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

N/A

- Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, perform the confirmation driving pattern and check the DTC judgment result again.

WIRING DIAGRAM

Refer to DTC P075511.

Click here .gif)

CAUTION / NOTICE / HINT

NOTICE:

-

Perform the universal trip to clear permanent DTCs.

Click here

.gif)

.gif)

-

Perform registration and/or initialization when parts related to the automatic transaxle are replaced.

Click here

.gif)

.gif)

.gif)

PROCEDURE

| 1. | CHECK HARNESS AND CONNECTOR (TRANSMISSION WIRE (SHIFT SOLENOID VALVE S2) - ECM) |

(a) Disconnect the D2 ECM connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| D2-77 (S2) - Body ground | 20°C (68°F) | 11 to 15 Ω |

| NG | .gif) | GO TO STEP 3 |

|

| 2. | REPLACE ECM |

(a) Replace the ECM.

Click here .gif)

| NEXT | .gif) | PERFORM A/T CODE REGISTRATION |

| 3. | CHECK HARNESS AND CONNECTOR (TRANSMISSION WIRE - ECM) |

(a) Disconnect the D56 transmission wire connector.

(b) Disconnect the D2 ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| D56-7 (SL) - D2-77 (S2) | Always | Below 1 Ω |

| D56-7 (SL) or D2-77 (S2) - Other terminals | Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR (TRANSMISSION WIRE - ECM) |

|

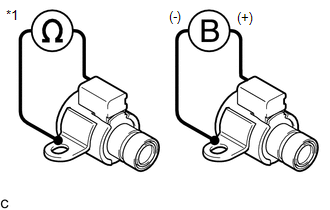

| 4. | INSPECT SHIFT SOLENOID VALVE S2 |

| (a) Remove the shift solenoid valve S2. Click here |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| Shift solenoid valve S2 connector terminal - Shift solenoid valve S2 Body | 20°C (68°F) | 11 to 15 Ω |

(c) Connect a positive (+) lead from the battery to the terminal of the solenoid valve connector, and a negative (-) lead to the solenoid body. Check that the valve moves and makes an operating sound.

OK:

Valve moves and makes an operating sound.

| OK | .gif) | REPAIR OR REPLACE TRANSMISSION WIRE |

| NG | .gif) | REPLACE SHIFT SOLENOID VALVE S2 |

Shift Solenoid "B" Circuit Short to Ground (P075511)

Shift Solenoid "B" Circuit Short to Ground (P075511)

DESCRIPTION Changing gears is performed by the ECM turning the shift solenoid valves SL1, SL2, SL3, SL4, SL5, S1 and S2 on and off. If an open or short occurs in any of the shift solenoid valve circui ...

Pressure Control Solenoid "B" Circuit Open (P077513)

Pressure Control Solenoid "B" Circuit Open (P077513)

DESCRIPTION Changing gears is performed by the ECM turning the shift solenoid valves SL1, SL2, SL3, SL4 and SL5 on and off. If an open or short occurs in any of the shift solenoid valve circuits, the ...

Other materials:

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Charging System: Terminals Of Ecm

TERMINALS OF ECM CHECK ECM HINT: The standard normal voltage between each pair of ECM terminals is shown in the table below. The appropriate conditions for checking each pair of terminals are also indicated. The result of checks should be compared with the standard normal voltage for that pair of t ...

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Glove Box Light: Removal

REMOVAL PROCEDURE 1. REMOVE INSTRUMENT PANEL GARNISH RH Click here 2. REMOVE FRONT DOOR SCUFF PLATE RH HINT: Use the same procedure as for the LH side. Click here 3. REMOVE COWL SIDE TRIM BOARD RH HINT: Use the same procedure as for the LH side. Click here 4. REMOVE NO. 2 INSTRUMENT P ...

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Owners Manual

- For your information

- Pictorial index

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Lexus Display Audio system

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Repair Manual

0.012

.gif)