Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual: Disassembly

DISASSEMBLY

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during engine unit removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

|---|---|---|---|

|

*1: When performing learning using the Techstream.

Click here | |||

| Disconnect cable from negative battery terminal | Memorize steering angle neutral point | Lane Control System | |

| Pre-collision system | |||

| Intelligent clearance sonar system*1 | |||

| Lighting system (w/ Automatic Headlight Beam Level Control System) | | ||

| Parking assist monitor system | | ||

| Panoramic view monitor system | | ||

| Initialize back door lock | Power door lock control system | | |

| Reset back door close position | Power Back Door System (w/ Outside Door Control Switch) | | |

| Replacement of ECM | Vehicle Identification Number (VIN) registration | MIL comes on | |

| ECU Communication ID Registration (Immobiliser system) | Engine start function | | |

| Perform code registration (Immobiliser system) |

| | |

| Inspection After Repair |

| |

| Replacement of automatic transaxle assembly | Perform the following procedures in the order shown:

|

| for U881E Registration: for U881E Initialization: for U881F Registration: for U881F Initialization: |

| Replacement of ECM (If possible, read the transaxle compensation code from the previous ECM) | Perform the following procedures in the order shown:

| ||

| Replacement of ECM (If impossible, read the transaxle compensation code from the previous ECM) | Perform the following procedures in the order shown:

| ||

| Front wheel alignment adjustment | Calibration |

| |

| Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

|

| |

| Rear television camera assembly optical axis (Back camera position setting) | Parking assist monitor system | for Initialization: for Calibration: | |

| Panoramic view monitor system | for Initialization: for Calibration: | |

| Initialize No. 1 headlight ECU sub-assembly LH | Lighting System (w/ Automatic Headlight Beam Level Control System) | | |

PROCEDURE

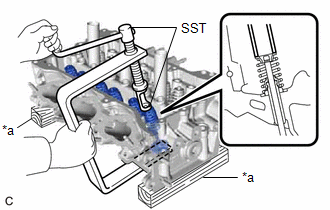

1. REMOVE INTAKE VALVE

| (a) Using SST and wooden blocks, compress the inner compression spring and remove the 6 valve spring retainer locks from the valve spring retainer. SST: 09202-70020 09202-01010 09202-01020 SST: 09202-00021 HINT: Arrange the removed parts in such a way that they can be reinstalled to their original locations. |

|

(b) Remove the 6 valve spring retainers, 6 inner compression springs and 6 intake valves from the cylinder head LH.

HINT:

Arrange the removed parts in such a way that they can be reinstalled to their original locations.

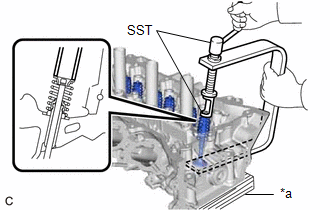

2. REMOVE EXHAUST VALVE

| (a) Using SST and wooden blocks, compress the inner compression spring and remove the 6 valve spring retainer locks from the valve spring retainer. SST: 09202-70020 09202-01010 09202-01020 SST: 09202-00021 HINT: Arrange the removed parts in such a way that they can be reinstalled to their original locations. |

|

(b) Remove the 6 valve spring retainers, 6 inner compression springs and 6 exhaust valves from the cylinder head LH.

HINT:

Arrange the removed parts in such a way that they can be reinstalled to their original locations.

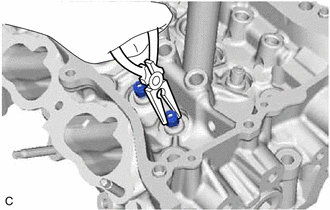

3. REMOVE INTAKE VALVE STEM OIL SEAL

| (a) Using needle-nose pliers, remove the 6 intake valve stem oil seals from the intake valve guide bush. |

|

4. REMOVE EXHAUST VALVE STEM OIL SEAL

HINT:

Use the same procedure as for the intake side.

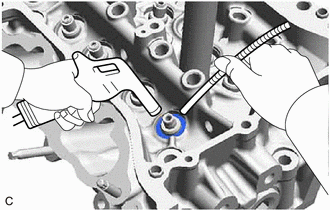

5. REMOVE VALVE SPRING SEAT

| (a) Using compressed air and a Magnet Hand, remove the 12 valve spring seats by blowing air onto them from the cylinder head LH. HINT: Arrange the removed parts in such a way that they can be reinstalled to their original locations. |

|

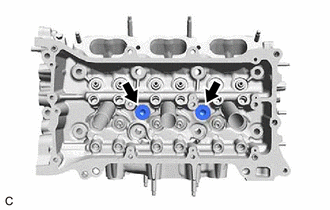

6. REMOVE NO. 1 STRAIGHT SCREW PLUG

NOTICE:

If coolant leaks from a No. 1 straight screw plug or a plug is corroded, replace it.

| (a) Using a 10 mm hexagon socket wrench, remove the 2 No. 1 straight screw plugs and 2 water hole gaskets from the cylinder head LH. |

|

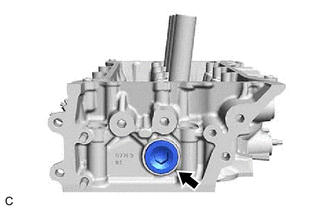

7. REMOVE NO. 2 STRAIGHT SCREW PLUG

NOTICE:

If coolant leaks from a No. 2 straight screw plug or a plug is corroded, replace it.

| (a) Using a 14 mm hexagon socket wrench, remove the No. 2 straight screw plug and cylinder head screw plug gasket from the cylinder head LH. |

|

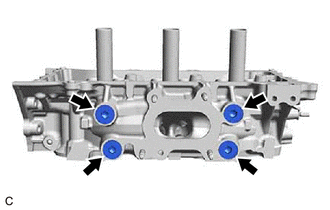

8. REMOVE NO. 3 STRAIGHT SCREW PLUG

NOTICE:

If coolant leaks from a No. 3 straight screw plug or a plug is corroded, replace it.

| (a) Using a 10 mm hexagon socket wrench, remove the 4 No. 3 straight screw plugs and 4 cylinder head screw plug gaskets from the cylinder head LH. |

|

Components

Components

COMPONENTS ILLUSTRATION *A w/ Stud Bolt - - *1 VALVE SPRING RETAINER LOCK *2 VALVE SPRING RETAINER *3 INNER COMPRESSION SPRING *4 INTAKE VALVE STEM OIL SEAL *5 VALV ...

Inspection

Inspection

INSPECTION CAUTION / NOTICE / HINT HINT:

Use the same procedure for bank 1 and bank 2.

The following procedure is for bank 2.

PROCEDURE 1. INSPECT CYLINDER HEAD LH (a) Using a precision straig ...

Other materials:

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Inner Rear View Mirror: Removal

REMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during inner rear view mirror assembly removal/installation are shown below. Necessary Procedure After Parts R ...

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Engine Unit: Removal

REMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during engine unit removal/installation are shown below. Necessary Procedure After Parts Removed/Installed/Rep ...

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Owners Manual

- For your information

- Pictorial index

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Lexus Display Audio system

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Repair Manual

0.0103

.gif)