Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during engine unit removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

|---|---|---|---|

|

*1: When performing learning using the Techstream.

Click here | |||

| Disconnect cable from negative battery terminal | Memorize steering angle neutral point | Lane Control System | |

| Pre-collision system | |||

| Intelligent clearance sonar system*1 | |||

| Lighting system (w/ Automatic Headlight Beam Level Control System) | | ||

| Parking assist monitor system | | ||

| Panoramic view monitor system | | ||

| Initialize back door lock | Power door lock control system | | |

| Reset back door close position | Power Back Door System (w/ Outside Door Control Switch) | | |

| Replacement of ECM | Vehicle Identification Number (VIN) registration | MIL comes on | |

| ECU Communication ID Registration (Immobiliser system) | Engine start function | | |

| Perform code registration (Immobiliser system) |

| | |

| Inspection After Repair |

| |

| Replacement of automatic transaxle assembly | Perform the following procedures in the order shown:

|

| for U881E Registration: for U881E Initialization: for U881F Registration: for U881F Initialization: |

| Replacement of ECM (If possible, read the transaxle compensation code from the previous ECM) | Perform the following procedures in the order shown:

| ||

| Replacement of ECM (If impossible, read the transaxle compensation code from the previous ECM) | Perform the following procedures in the order shown:

| ||

| Front wheel alignment adjustment | Calibration |

| |

| Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

|

| |

| Rear television camera assembly optical axis (Back camera position setting) | Parking assist monitor system | for Initialization: for Calibration: | |

| Panoramic view monitor system | for Initialization: for Calibration: | |

| Initialize No. 1 headlight ECU sub-assembly LH | Lighting System (w/ Automatic Headlight Beam Level Control System) | | |

PROCEDURE

1. REMOVE KNOCK CONTROL SENSOR

Click here .gif)

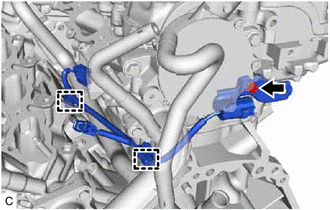

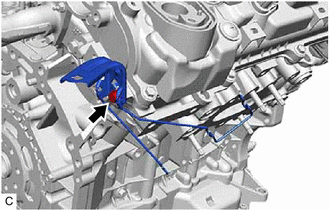

2. REMOVE SENSOR WIRE

| (a) Disengage the 2 clamps and remove the bolt and sensor wire from the water inlet pipe. |

|

3. REMOVE IGNITION COIL ASSEMBLY

Click here .gif)

4. REMOVE VACUUM PUMP ASSEMBLY

Click here .gif)

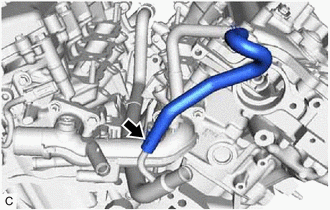

5. REMOVE NO. 3 WATER BY-PASS HOSE

| (a) Slide the clip and remove the No. 3 water by-pass hose from the water inlet pipe. |

|

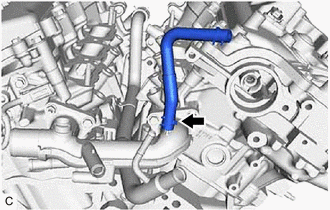

6. REMOVE NO. 2 WATER BY-PASS HOSE

| (a) Slide the clip and remove the No. 2 water by-pass hose from the water outlet. |

|

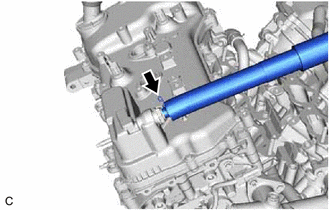

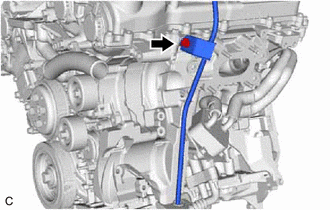

7. REMOVE VENTILATION HOSE

| (a) Slide the clip and remove the ventilation hose from the PCV valve (ventilation valve sub-assembly). |

|

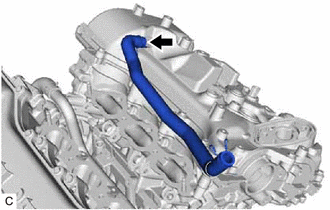

8. REMOVE NO. 2 VENTILATION HOSE

| (a) Slide the clip and remove the No. 2 ventilation hose from the cylinder head cover sub-assembly. |

|

9. REMOVE V-RIBBED BELT

Click here .gif)

10. REMOVE GENERATOR ASSEMBLY

-

for 180A Type:

Click here

.gif)

-

for 150A Type:

Click here

.gif)

11. REMOVE COMPRESSOR AND MAGNETIC CLUTCH

Click here .gif)

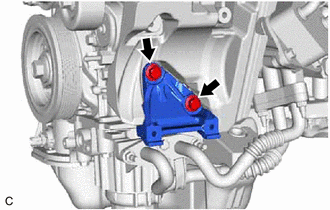

12. REMOVE NO. 1 COMPRESSOR MOUNTING BRACKET

| (a) Remove the 2 bolts and No. 1 compressor mounting bracket from the cylinder block sub-assembly. |

|

13. REMOVE NO. 2 IDLER PULLEY SUB-ASSEMBLY

Click here .gif)

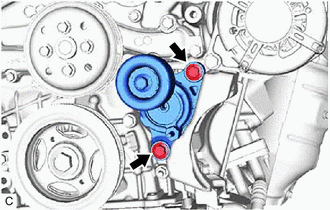

14. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

| (a) Remove the 2 bolts and V-ribbed belt tensioner assembly. |

|

15. REMOVE WATER PUMP PULLEY

Click here .gif)

16. REMOVE ENGINE OIL LEVEL DIPSTICK GUIDE

(a) Remove the engine oil level dipstick from the engine oil level dipstick guide.

| (b) Remove the bolt and engine oil level dipstick guide from the camshaft housing sub-assembly LH and oil pan sub-assembly. |

|

| (c) Remove the engine oil level dipstick guide O-ring from the engine oil level dipstick guide. |

|

17. REMOVE NO. 5 CYLINDER BLOCK INSULATOR (w/ Oil Cooler)

| (a) Remove the No. 5 cylinder block insulator from the engine assembly. |

|

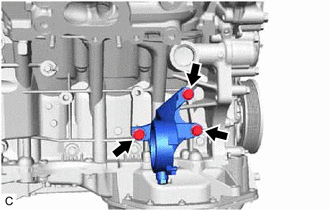

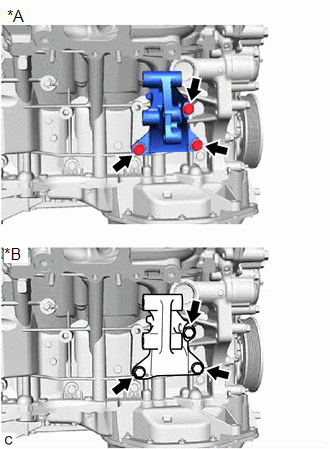

18. REMOVE DRIVE SHAFT BEARING BRACKET (for 2WD)

| (a) Remove the 3 bolts and drive shaft bearing bracket from the cylinder block sub-assembly. |

|

19. REMOVE NO. 2 TRANSFER STIFFENER PLATE (for AWD)

| (a) Remove the 3 bolts and No. 2 transfer stiffener plate from the cylinder block sub-assembly. |

|

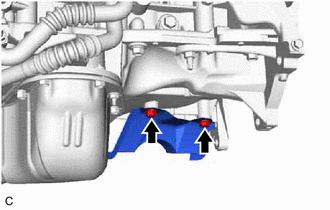

20. REMOVE NO. 1 EXHAUST PIPE SUPPORT BRACKET

| (a) Remove the 2 bolts and No. 1 exhaust pipe support bracket from the oil pan sub-assembly. |

|

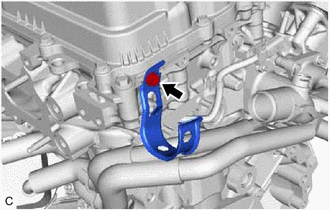

21. REMOVE WIRE HARNESS CLAMP BRACKET

| (a) Remove the bolt and wire harness clamp bracket from the camshaft housing sub-assembly. |

|

22. REMOVE RADIATOR PIPE CLAMP

| (a) Remove the bolt and radiator pipe clamp from the camshaft housing sub-assembly LH. |

|

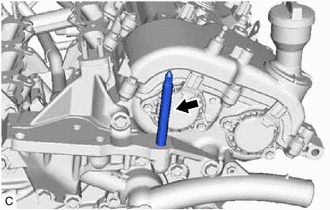

23. REMOVE STUD BOLT

NOTICE:

If a stud bolt is deformed or its threads are damaged, replace it.

| (a) Using an 8 mm socket wrench, remove the stud bolt from the front No. 1 engine mounting bracket LH. |

|

Components

Components

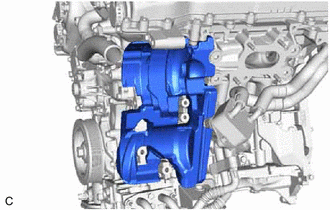

COMPONENTS ILLUSTRATION *A for 2WD *B for AWD *C Type A *D Type B *E w/ Oil Cooler - - *1 IGNITION COIL ASSEMBLY *2 VACUUM PUMP ASSEMBLY *3 NO. 2 WATER BY ...

Inspection

Inspection

INSPECTION PROCEDURE 1. INSPECT NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY (a) Turn the roller by hand to check that it turns smoothly. HINT: If the roller does not turn smoothly, replace the No. 1 valve ...

Other materials:

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Window Defogger System: How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT HINT:

Use the following procedure to troubleshoot the window defogger system.

*: Use the Techstream.

PROCEDURE 1. VEHICLE BROUGHT TO WORKSHOP

NEXT 2. CUSTOMER PROBLEM ANALYSIS HINT:

In troubleshooting, confirm that the problem sym ...

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Rear No. 1 Seat Outer Belt Assembly: Disposal

DISPOSAL CAUTION / NOTICE / HINT CAUTION: Before performing pre-disposal deployment of any SRS part, review and closely follow all applicable environmental and hazardous material regulations. Pre-disposal deployment may be considered hazardous material treatment. PROCEDURE 1. PRECAUTION CAUTION:

...

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Owners Manual

- For your information

- Pictorial index

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Lexus Display Audio system

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Repair Manual

0.0156