Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during engine oil level sensor removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

|---|---|---|---|

| Front wheel alignment adjustment |

|

| |

| Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

|

| |

| Rear television camera assembly optical axis (Back camera position setting) | Parking assist monitor system | for Initialization for Calibration | |

| Panoramic view monitor system | for Initialization for Calibration | |

| Initialize headlight ECU sub-assembly LH |

| | |

| Replacement of throttle body with motor assembly | Inspection After Repair |

| |

| Cleaning the deposits from the throttle body with motor assembly | |||

| Air leaks from intake system is repaired | |||

| Gas leak from exhaust system is repaired | |||

| Battery terminal is disconnected/reconnected | Memorize steering angle neutral point | Lane Control System | |

| Pre-collision system | |||

| Intelligent clearance sonar system*1 | |||

| Parking assist monitor system | | ||

| Panoramic view monitor system | | ||

| Lighting system (w/ Automatic Headlight Beam Level Control System) | | ||

| Initialize back door lock | Power door lock control system | | |

| Reset back door close position | Power Back Door System (w/ Outside Door Control Switch) | | |

| Replacement of ECM (If possible, read the transaxle compensation code from the previous ECM) | Perform the following procedures in the order shown:

|

| for U881E Registration: for U881E Initialization: for U881F Registration: for U881F Initialization: |

| Replacement of ECM (If impossible, read the transaxle compensation code from the previous ECM) | Perform the following procedures in the order shown:

| ||

| Replacement of ECM | Vehicle Identification Number (VIN) registration | MIL comes on | |

| ECU communication ID registration (Immobiliser system) | Engine start function | | |

| Perform code registration (Immobiliser system) |

|

PROCEDURE

1. DRAIN ENGINE OIL

Click here .gif)

.gif)

2. REMOVE FRONT FRAME ASSEMBLY

Click here .gif)

3. REMOVE NO. 2 OIL PAN SUB-ASSEMBLY

Click here .gif)

4. REMOVE OIL STRAINER SUB-ASSEMBLY

Click here .gif)

5. REMOVE ENGINE OIL LEVEL SENSOR

(a) Disconnect the engine oil level sensor connector.

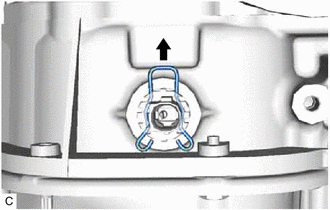

| (b) Remove the clip from the engine oil level sensor. |

|

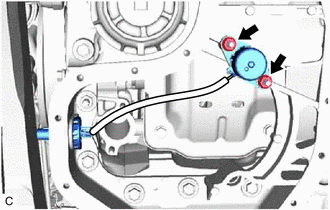

| (c) Remove the 2 bolts and engine oil level sensor. |

|

Inspection

Inspection

INSPECTION PROCEDURE 1. INSPECT ENGINE OIL LEVEL SENSOR (a) Measure the resistance according to the value(s) in the table below. Standard Resistance: Tester Connection Condition Specified C ...

Installation

Installation

INSTALLATION PROCEDURE 1. INSTALL ENGINE OIL LEVEL SENSOR (a) Install the engine oil level sensor with the 2 bolts. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} (b) Install a new clip to the engine oil l ...

Other materials:

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Rear Brake Flexible Hose: Components

COMPONENTS ILLUSTRATION *1 NO. 2 FLEXIBLE HOSE BRACKET *2 REAR FLEXIBLE HOSE *3 GASKET - - Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) N*m (kgf*cm, ft.*lbf): Specified torque * F ...

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Smart Access System With Push-button Start (for Start Function): Engine/Power Switch Malfunction (B2278)

DESCRIPTION This DTC is stored when the SSW1 contact signal and SSW2 contact signal, which are detected when the engine switch is operated, do not match. DTC No. Detection Item DTC Detection Condition Trouble Area Note B2278 Engine/Power Switch Malfunction When the engine switch i ...

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Owners Manual

- For your information

- Pictorial index

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Lexus Display Audio system

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Repair Manual

0.0088