Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual: Headlight Swivel ECU LH Communication (B2410,B2411)

DESCRIPTION

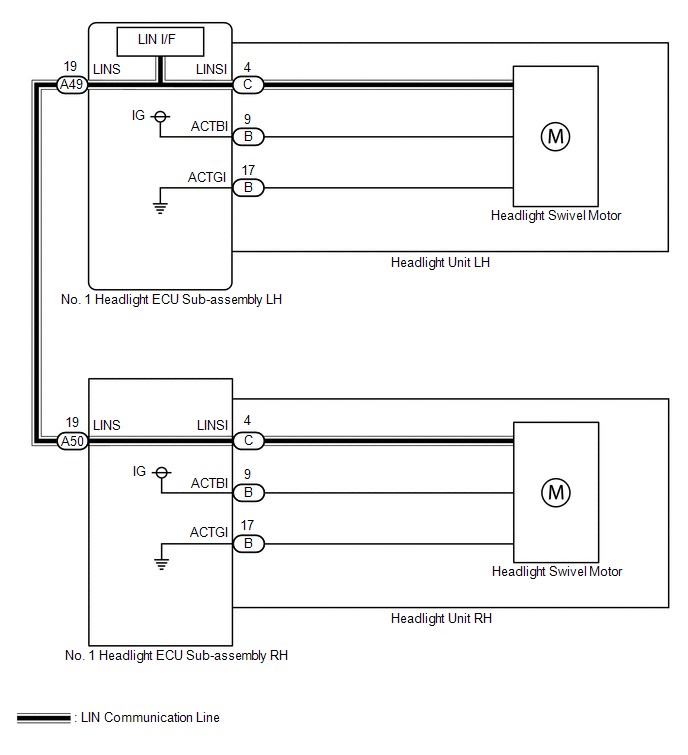

Each No. 1 headlight ECU sub-assembly and headlight swivel motor communicate via LIN communication.

The headlight swivel motor operates according to power supplied and automatic headlight beam level control signals from its respective No. 1 headlight ECU sub-assembly and sends its operating state to the No. 1 headlight ECU sub-assembly.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | DTC Output from |

|---|---|---|---|---|

| B2410 | Headlight Swivel ECU LH Communication |

|

| AFS |

| B2411 | Headlight Swivel ECU RH Communication |

|

| AFS |

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

-

If the No. 1 headlight ECU sub-assembly LH has been replaced, it is necessary to synchronize the vehicle information and initialize the No. 1 headlight ECU sub-assembly LH.

Click here

.gif)

.gif)

-

If the headlight assembly LH has been replaced, it is necessary to synchronize the vehicle information and initialize the No. 1 headlight ECU sub-assembly LH.*

Click here

.gif)

.gif)

- When replacing the No. 1 headlight ECU sub-assembly LH, always replace it with a new one. If a No. 1 headlight ECU sub-assembly LH which was installed to another vehicle is used, the information stored in it will not match the information from the vehicle and a DTC may be stored.

-

When replacing the headlight assembly LH, always replace it with a new one. If a headlight assembly LH which was installed to another vehicle is used, the information stored in it will not match the information from the vehicle and a DTC may be stored.*

- *: for TMMC Made

PROCEDURE

| 1. | CLEAR DTC |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / AFS / Trouble Codes.

(e) Clear the DTCs.

Body Electrical > AFS > Clear DTCs

|

| 2. | CHECK FOR DTC |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Wait 10 seconds or more.

(d) Turn the Techstream on.

(e) Enter the following menus: Body Electrical / AFS / Trouble Codes.

(f) Check for DTCs.

Body Electrical > AFS > Trouble CodesOK:

DTC B2410 and B2411 are not output.

| Result | Proceed to |

|---|---|

| OK | A |

| NG (DTC B2410 is output) | B |

| NG (DTC B2411 is output) | C |

| NG (DTC B2410 and B2411 are output) | D |

| A | .gif) | USE SIMULATION METHOD TO CHECK |

| C | .gif) | GO TO STEP 4 |

| D | .gif) | GO TO STEP 7 |

|

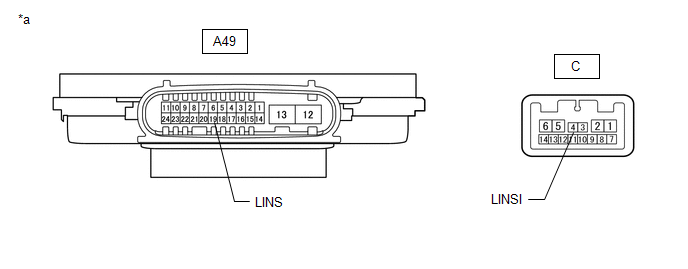

| 3. | INSPECT NO. 1 HEADLIGHT ECU SUB-ASSEMBLY LH |

| *a | Component without harness connected (No. 1 Headlight ECU Sub-assembly LH) | - | - |

(a) Remove the No. 1 headlight ECU sub-assembly LH.

Click here .gif)

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A49-19 (LINS) - C-4 (LINSI) | Always | Below 1 Ω |

| Result | Proceed to |

|---|---|

| OK (for TMC Made) | A |

| OK (for TMMC Made) | B |

| NG | C |

| A | .gif) | REPLACE HEADLIGHT UNIT LH |

| B | .gif) | REPLACE HEADLIGHT ASSEMBLY LH |

| C | .gif) | REPLACE NO. 1 HEADLIGHT ECU SUB-ASSEMBLY LH |

| 4. | CHECK HARNESS AND CONNECTOR (NO. 1 HEADLIGHT ECU SUB-ASSEMBLY LH - NO. 1 HEADLIGHT ECU SUB-ASSEMBLY RH) |

(a) Disconnect the A49 No. 1 headlight ECU sub-assembly LH connector.

(b) Disconnect the A50 No. 1 headlight ECU sub-assembly RH connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A49-19 (LINS) - A50-19 (LINS) | Always | Below 1 Ω |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 5. | CHECK NO. 1 HEADLIGHT ECU SUB-ASSEMBLY LH (LINS TERMINAL SIGNAL OUTPUT) |

| *a | Front view of wire harness connector (to No. 1 Headlight ECU Sub-assembly RH) |

(a) Connect the A49 No. 1 headlight ECU sub-assembly LH connector.

(b) Using a Techstream, check the waveform.

OK:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A50-19 (LINS) - Body ground | Engine switch on (IG) | Pulse generation |

| NG | .gif) | REPLACE NO. 1 HEADLIGHT ECU SUB-ASSEMBLY LH |

|

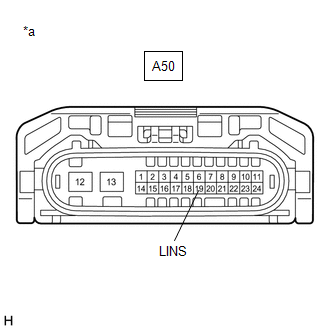

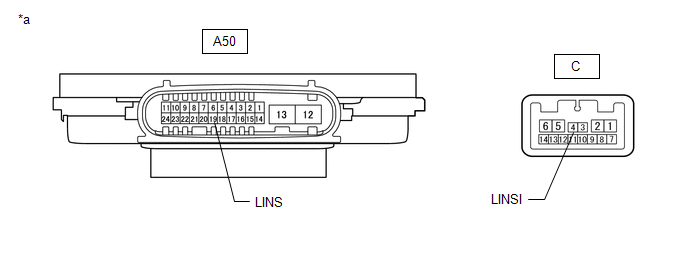

| 6. | INSPECT NO. 1 HEADLIGHT ECU SUB-ASSEMBLY RH |

| *a | Component without harness connected (No. 1 Headlight ECU Sub-assembly RH) | - | - |

(a) Remove the No. 1 headlight ECU sub-assembly RH.

Click here .gif)

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A50-19 (LINS) - C-4 (LINSI) | Always | Below 1 Ω |

| Result | Proceed to |

|---|---|

| OK (for TMC Made) | A |

| OK (for TMMC Made) | B |

| NG | C |

| A | .gif) | REPLACE HEADLIGHT UNIT RH |

| B | .gif) | REPLACE HEADLIGHT ASSEMBLY RH |

| C | .gif) | REPLACE NO. 1 HEADLIGHT ECU SUB-ASSEMBLY RH |

| 7. | CHECK HARNESS AND CONNECTOR (NO. 1 HEADLIGHT ECU SUB-ASSEMBLY LH - NO. 1 HEADLIGHT ECU SUB-ASSEMBLY RH) |

(a) Disconnect the A49 No. 1 headlight ECU sub-assembly LH connector.

(b) Disconnect the A50 No. 1 headlight ECU sub-assembly RH connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A49-19 (LINS) or A50-19 (LINS) - Body ground | Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 8. | CLEAR DTC |

(a) Connect the A49 No. 1 headlight ECU sub-assembly LH connector.

(b) Connect the Techstream to the DLC3.

(c) Turn the engine switch on (IG).

(d) Turn the Techstream on.

(e) Enter the following menus: Body Electrical / AFS / Trouble Codes.

(f) Clear the DTCs.

Body Electrical > AFS > Clear DTCs

|

| 9. | CHECK FOR DTC |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Wait 10 seconds or more.

(d) Turn the Techstream on.

(e) Enter the following menus: Body Electrical / AFS / Trouble Codes.

(f) Check for DTCs.

Body Electrical > AFS > Trouble Codes| Result | Proceed to |

|---|---|

| DTC B2411 is output | A |

| DTC B2410 and B2411 are output | B |

| B | .gif) | GO TO STEP 13 |

|

| 10. | CHECK NO. 1 HEADLIGHT ECU SUB-ASSEMBLY RH |

(a) Remove the No. 1 headlight ECU sub-assembly RH.

Click here .gif)

(b) Connect the A50 No. 1 headlight ECU sub-assembly RH connector.

|

| 11. | CLEAR DTC |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / AFS / Trouble Codes.

(e) Clear the DTCs.

Body Electrical > AFS > Clear DTCs

|

| 12. | CHECK FOR DTC |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Wait 10 seconds or more.

(d) Turn the Techstream on.

(e) Enter the following menus: Body Electrical / AFS / Trouble Codes.

(f) Check for DTCs.

Body Electrical > AFS > Trouble Codes| Result | Proceed to |

|---|---|

| DTC B2411 is output (for TMC Made) | A |

| DTC B2411 is output (for TMMC Made) | B |

| DTC B2410 and B2411 are output | C |

| A | .gif) | REPLACE HEADLIGHT UNIT RH |

| B | .gif) | REPLACE HEADLIGHT ASSEMBLY RH |

| C | .gif) | REPLACE NO. 1 HEADLIGHT ECU SUB-ASSEMBLY RH |

| 13. | CHECK NO. 1 HEADLIGHT ECU SUB-ASSEMBLY LH |

(a) Remove the No. 1 headlight ECU sub-assembly LH.

Click here .gif)

(b) Connect the A49 No. 1 headlight ECU sub-assembly LH connector.

(c) Connect the A50 No. 1 headlight ECU sub-assembly RH connector.

|

| 14. | CLEAR DTC |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / AFS / Trouble Codes.

(e) Clear the DTCs.

Body Electrical > AFS > Clear DTCs

|

| 15. | CHECK FOR DTC |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Wait 10 seconds or more.

(d) Turn the Techstream on.

(e) Enter the following menus: Body Electrical / AFS / Trouble Codes.

(f) Check for DTCs.

Body Electrical > AFS > Trouble Codes| Result | Proceed to |

|---|---|

| DTC B2410 is output (for TMC Made) | A |

| DTC B2410 is output (for TMMC Made) | B |

| DTC B2410 and B2411 are output | C |

| A | .gif) | REPLACE HEADLIGHT UNIT LH |

| B | .gif) | REPLACE HEADLIGHT ASSEMBLY LH |

| C | .gif) | REPLACE NO. 1 HEADLIGHT ECU SUB-ASSEMBLY LH |

Automatic High Beam Camera (B124C)

Automatic High Beam Camera (B124C)

DESCRIPTION The main body ECU (multiplex network body ECU) detects a high beam headlight illumination request signal of the automatic high beam system from the forward recognition camera. DTC No. ...

Headlight Swivel Motor LH (B2412,B2413,B2417,B2418)

Headlight Swivel Motor LH (B2412,B2413,B2417,B2418)

DESCRIPTION The No. 1 headlight ECU sub-assembly LH sends automatic headlight beam level control signals to each headlight swivel motor and headlight leveling motor via LIN communication. Each No. 1 h ...

Other materials:

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Rear Combination Light Assembly (w/ Rear No. 2 Seat): Inspection

INSPECTION PROCEDURE 1. INSPECT REAR COMBINATION LIGHT ASSEMBLY LH (a) Apply battery voltage to the rear combination light assembly LH and check that the lights come on. OK: Condition Specified Condition Battery positive (+) → Terminal 1 (B) Battery negative (-) → Terminal 3 (E) T ...

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Electric Parking Brake System: Precaution

PRECAUTION PRECAUTION FOR DISCONNECTING CABLE FROM NEGATIVE BATTERY TERMINAL NOTICE: When disconnecting the cable from the negative (-) battery terminal, initialize the following system(s) after the cable is reconnected. System See Procedure Lane Control System Pre-collision System ...

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Owners Manual

- For your information

- Pictorial index

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Lexus Display Audio system

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Repair Manual

0.0108

.gif)