Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual: Components

COMPONENTS

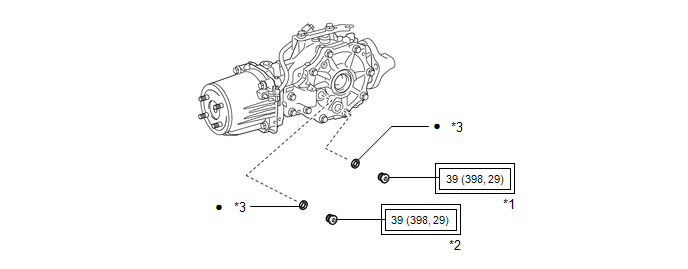

ILLUSTRATION

| *1 | REAR DIFFERENTIAL DRAIN PLUG | *2 | DIFFERENTIAL INSPECTION PLUG |

| *3 | GASKET | - | - |

.png) | Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) | ● | Non-reusable part |

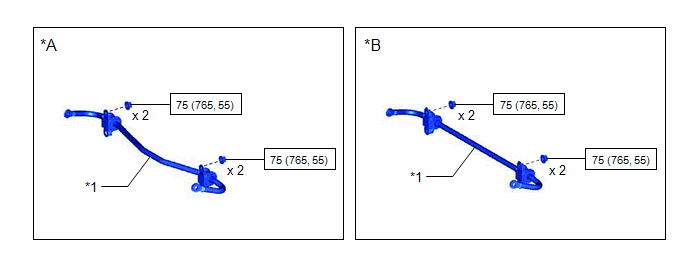

ILLUSTRATION

| *A | w/ Rear No. 2 Seat | *B | w/o Rear No. 2 Seat |

| *1 | REAR STABILIZER BAR | - | - |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | - | - |

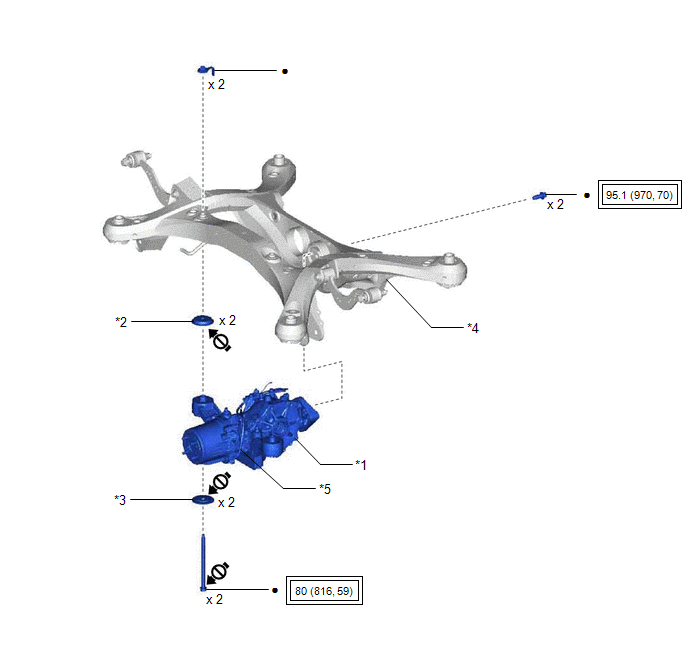

ILLUSTRATION

| *1 | REAR DIFFERENTIAL CARRIER ASSEMBLY WITH DIFFERENTIAL SUPPORT | *2 | UPPER REAR DIFFERENTIAL MOUNT STOPPER |

| *3 | LOWER REAR DIFFERENTIAL MOUNT STOPPER | *4 | REAR SUSPENSION MEMBER SUB-ASSEMBLY |

| *5 | VACUUM HOSE | - | - |

.png) | Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) | ● | Non-reusable part |

.png) | Do not apply lubricants | - | - |

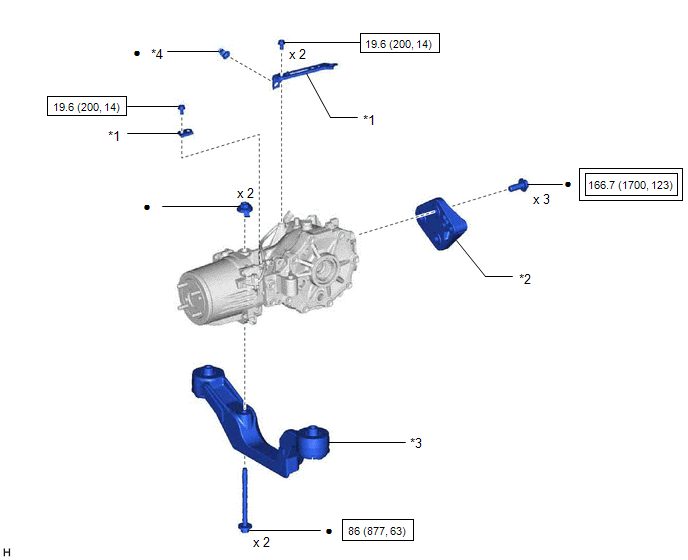

ILLUSTRATION

| *1 | CONNECTOR BRACKET | *2 | DIFFERENTIAL SUPPORT |

| *3 | NO. 2 REAR DIFFERENTIAL SUPPORT | *4 | CLAMP |

.png) | Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) | .png) | N*m (kgf*cm, ft.*lbf): Specified torque |

| ● | Non-reusable part | - | - |

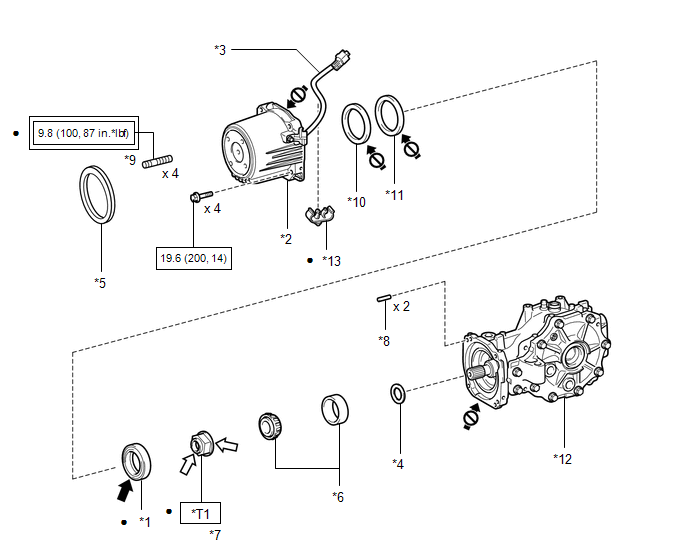

ILLUSTRATION

| *1 | DIAPHRAGM OIL SEAL | *2 | ELECTRO MAGNETIC CONTROL COUPLING SUB-ASSEMBLY |

| *3 | ELECTRO MAGNETIC CONTROL COUPLING WIRE HARNESS | *4 | REAR DIFFERENTIAL DRIVE PINION OIL SLINGER |

| *5 | REAR DIFFERENTIAL DUST DEFLECTOR | *6 | REAR DRIVE PINION FRONT TAPERED ROLLER BEARING |

| *7 | REAR DRIVE PINION NUT | *8 | STRAIGHT PIN |

| *9 | STUD BOLT | *10 | TRANSMISSION COUPLING CONICAL SPRING WASHER |

| *11 | TRANSMISSION COUPLING SPACER | *12 | REAR DIFFERENTIAL CARRIER ASSEMBLY |

| *13 | CLAMP | - | - |

.png) | Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) | .png) | N*m (kgf*cm, ft.*lbf): Specified torque |

| *T1 | For use without SST: 321 N*m (3273 kgf*cm, 237 ft.*lbf) or less For use with SST: 307 N*m (3131 kgf*cm, 226 ft.*lbf) or less | ● | Non-reusable part |

.png) | MP grease |  | Hypoid gear oil LSD |

.png) | Do not apply lubricants | - | - |

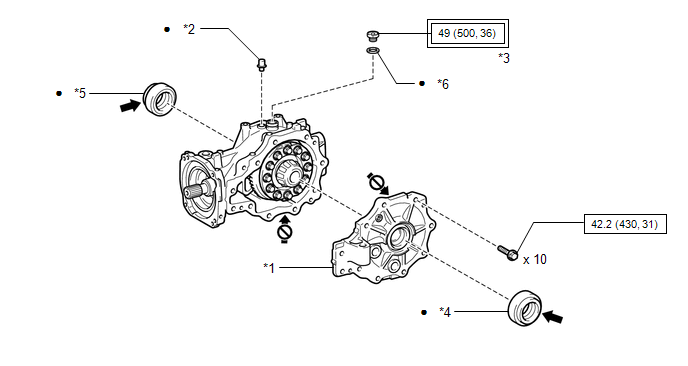

ILLUSTRATION

| *1 | DIFFERENTIAL SIDE BEARING RETAINER | *2 | REAR DIFFERENTIAL CARRIER COVER BREATHER PLUG |

| *3 | REAR DIFFERENTIAL FILLER PLUG | *4 | REAR DRIVE SHAFT OIL SEAL LH |

| *5 | REAR DRIVE SHAFT OIL SEAL RH | *6 | GASKET |

.png) | Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) | .png) | N*m (kgf*cm, ft.*lbf): Specified torque |

| ● | Non-reusable part | .png) | MP grease |

.png) | Do not apply lubricants | - | - |

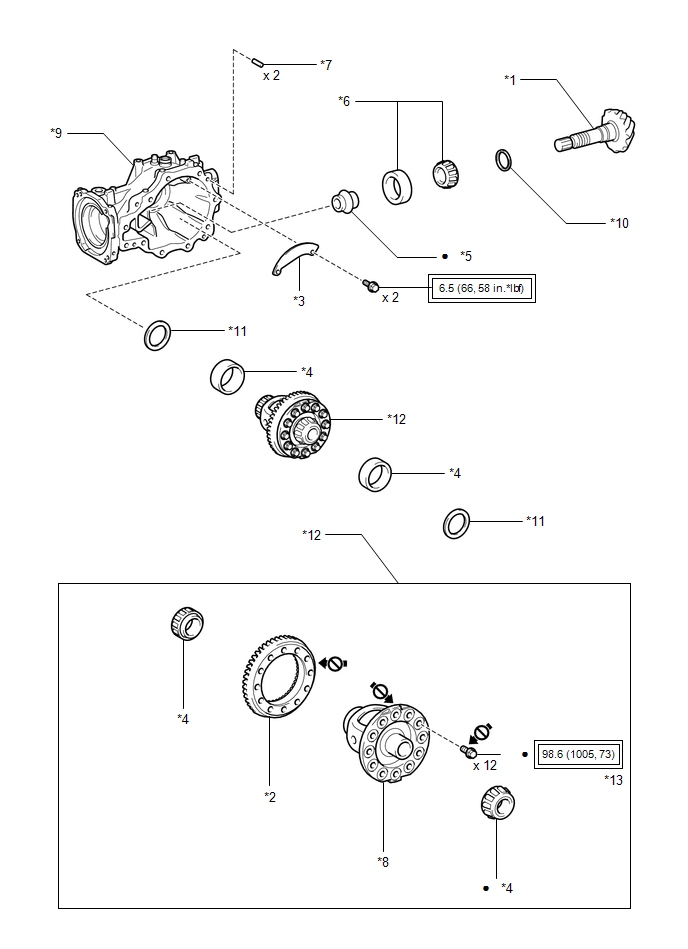

ILLUSTRATION

| *1 | DIFFERENTIAL DRIVE PINION | *2 | DIFFERENTIAL RING GEAR |

| *3 | REAR DIFFERENTIAL BREATHER PLUG OIL DEFLECTOR | *4 | REAR DIFFERENTIAL CASE BEARING |

| *5 | REAR DIFFERENTIAL DRIVE PINION BEARING SPACER | *6 | REAR DRIVE PINION REAR TAPERED ROLLER BEARING |

| *7 | STRAIGHT PIN | *8 | REAR DIFFERENTIAL CASE SUB-ASSEMBLY |

| *9 | REAR DIFFERENTIAL CARRIER | *10 | REAR DIFFERENTIAL DRIVE PINION PLATE WASHER |

| *11 | REAR DIFFERENTIAL SIDE GEAR SHAFT PLATE WASHER | *12 | REAR DIFFERENTIAL CASE ASSEMBLY |

| *13 | REAR DIFFERENTIAL CASE BOLT | - | - |

.png) | Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) | ● | Non-reusable part |

| ★ | Precoated Part | .png) | Do not apply lubricants |

Removal

Removal

REMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during rea ...

Other materials:

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Smart Access System With Push-button Start (for Start Function): Engine/Power Switch Malfunction (B2278)

DESCRIPTION This DTC is stored when the SSW1 contact signal and SSW2 contact signal, which are detected when the engine switch is operated, do not match. DTC No. Detection Item DTC Detection Condition Trouble Area Note B2278 Engine/Power Switch Malfunction When the engine switch i ...

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Fuel Pressure Sensor: Removal

REMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during fuel pressure sensor removal/installation are shown below. Necessary Procedures After Parts Removed/Inst ...

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Owners Manual

- For your information

- Pictorial index

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Lexus Display Audio system

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Repair Manual

0.1246