Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual: Components

COMPONENTS

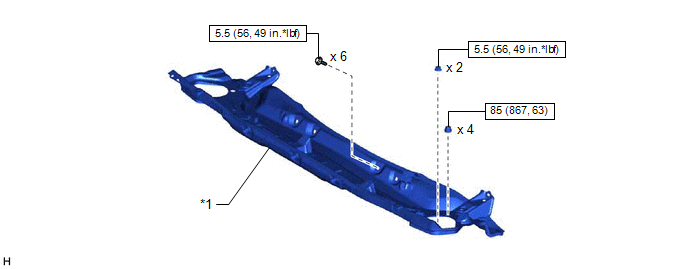

ILLUSTRATION

| *1 | OUTER COWL TOP PANEL SUB-ASSEMBLY | - | - |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | - | - |

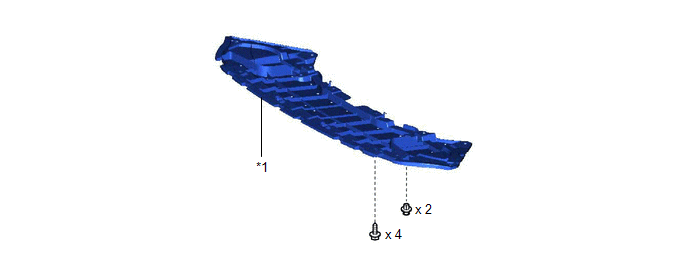

ILLUSTRATION

.png)

| *1 | FRONT WHEEL OPENING EXTENSION PAD LH | *2 | NO. 3 ENGINE UNDER COVER |

| *3 | FRONT FENDER APRON SEAL LH | - | - |

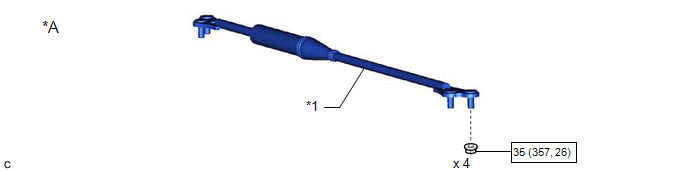

ILLUSTRATION

| *1 | FRONT LOWER BUMPER ABSORBER | - | - |

ILLUSTRATION

| *A | w/ Suspension Tower Damper | - | - |

| *1 | SUSPENSION TOWER DAMPER | - | - |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | - | - |

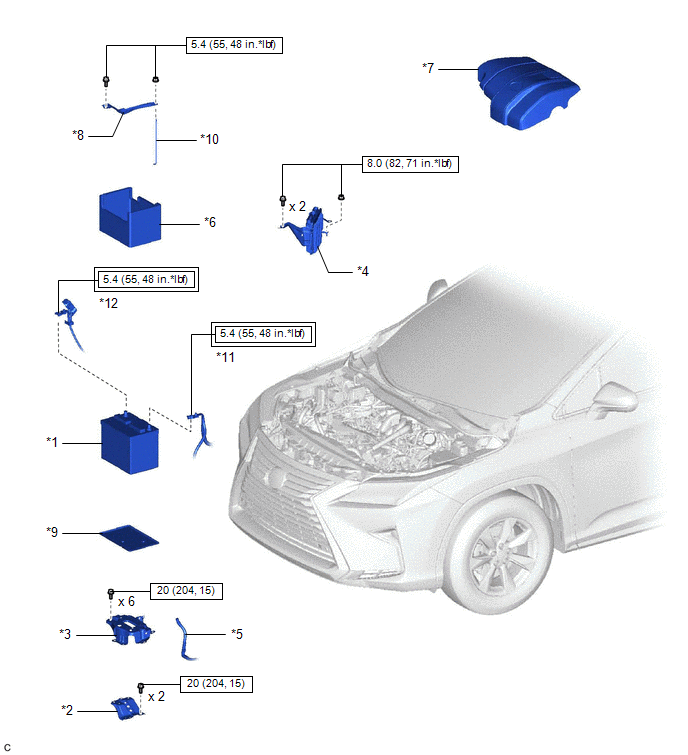

ILLUSTRATION

| *1 | BATTERY | *2 | BATTERY BRACKET REINFORCEMENT |

| *3 | BATTERY CARRIER SUB-ASSEMBLY | *4 | ECM |

| *5 | ENGINE WIRE | *6 | BATTERY INSULATOR |

| *7 | V-BANK COVER SUB-ASSEMBLY | *8 | BATTERY CLAMP SUB-ASSEMBLY |

| *9 | BATTERY TRAY | *10 | BATTERY CLAMP BOLT |

| *11 | NEGATIVE BATTERY TERMINAL | *12 | POSITIVE BATTERY TERMINAL |

.png) | Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) | .png) | N*m (kgf*cm, ft.*lbf): Specified torque |

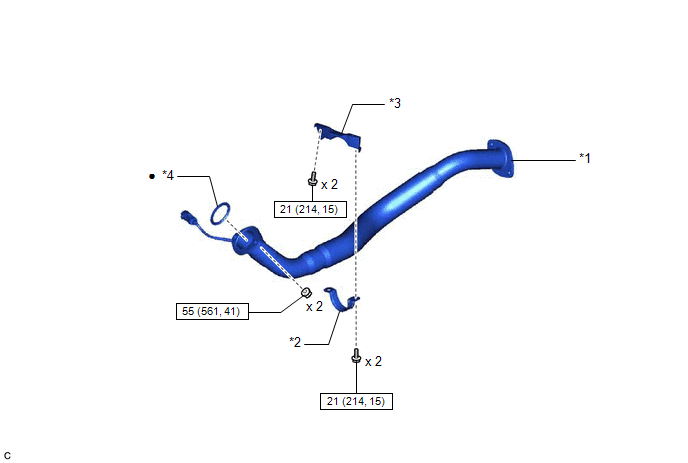

ILLUSTRATION

| *1 | FRONT EXHAUST PIPE ASSEMBLY | *2 | NO. 1 EXHAUST PIPE SUPPORT BRACKET (for Lower Side) |

| *3 | NO. 1 EXHAUST PIPE SUPPORT BRACKET | *4 | EXHAUST PIPE GASKET |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

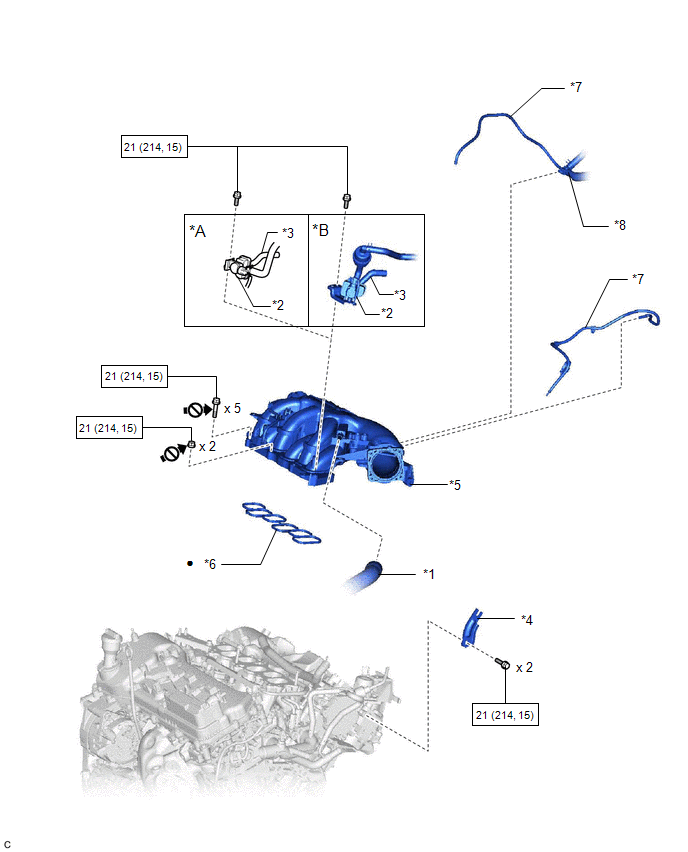

ILLUSTRATION

| *A | for TMMC Made | *B | except TMMC Made |

| *1 | VENTILATION HOSE | *2 | PURGE VALVE (PURGE VSV) |

| *3 | NO. 1 FUEL VAPOR FEED HOSE | *4 | NO. 2 SURGE TANK STAY |

| *5 | INTAKE AIR SURGE TANK ASSEMBLY | *6 | AIR SURGE TANK TO INTAKE MANIFOLD GASKET |

| *7 | VACUUM HOSE SUB-ASSEMBLY | *8 | NO. 2 AIR TUBE |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

.png) | Do not apply lubricants (to the threaded parts) | - | - |

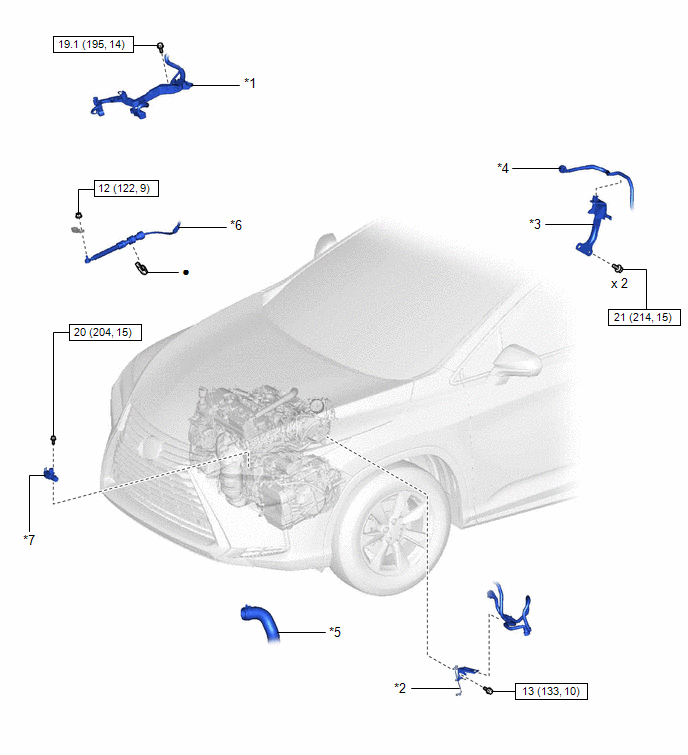

ILLUSTRATION

| *1 | WIRE HARNESS | *2 | WIRE HARNESS CLAMP BRACKET |

| *3 | FUEL PUMP PROTECTOR | *4 | FUEL TUBE SUB-ASSEMBLY |

| *5 | NO. 1 RADIATOR HOSE | *6 | TRANSMISSION CONTROL CABLE ASSEMBLY |

| *7 | NO. 2 VACUUM SWITCHING VALVE ASSEMBLY | - | - |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

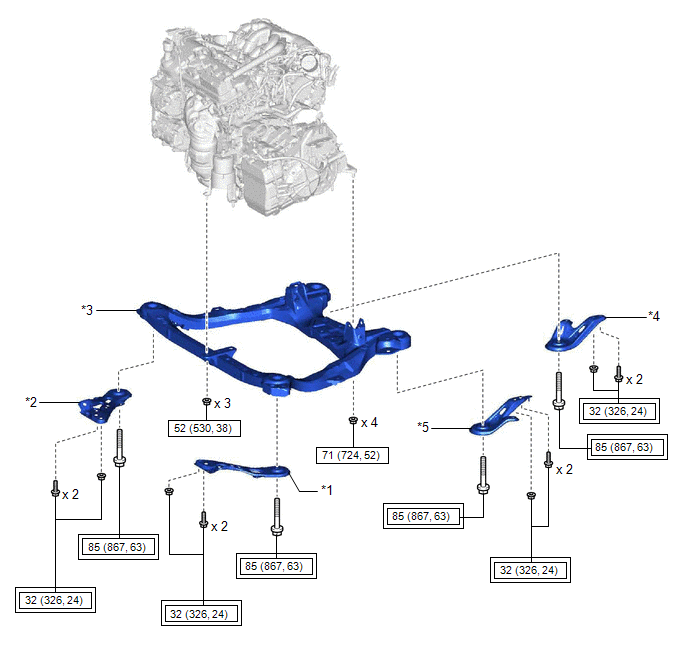

ILLUSTRATION

| *1 | FRAME SIDE RAIL PLATE SUB-ASSEMBLY LH | *2 | FRAME SIDE RAIL PLATE SUB-ASSEMBLY RH |

| *3 | FRONT FRAME ASSEMBLY | *4 | FRONT SUSPENSION MEMBER BRACKET SUB-ASSEMBLY RH |

| *5 | FRONT SUSPENSION MEMBER BRACKET SUB-ASSEMBLY LH | - | - |

.png) | N*m (kgf*cm, ft.*lbf): Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" | .png) | N*m (kgf*cm, ft.*lbf): Specified torque |

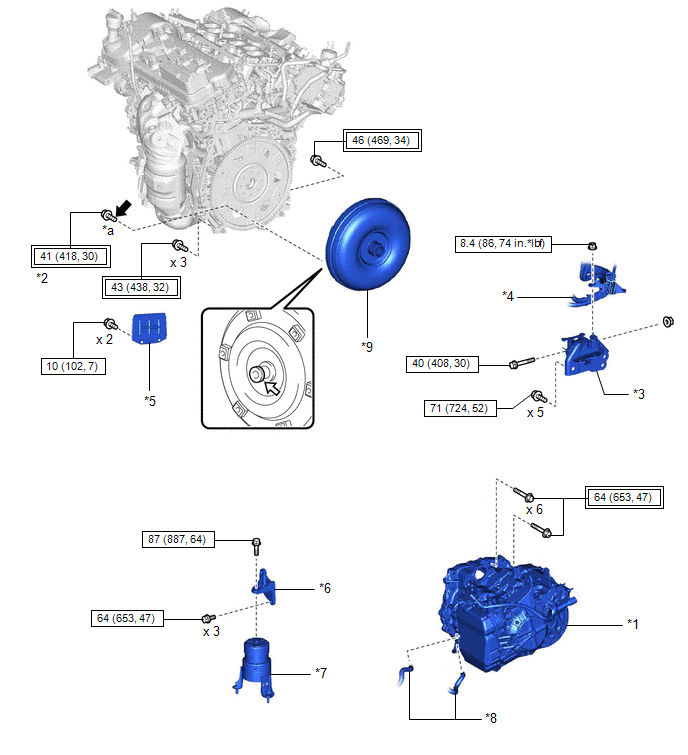

ILLUSTRATION

| *1 | AUTOMATIC TRANSAXLE ASSEMBLY | *2 | DRIVE PLATE AND TORQUE CONVERTER ASSEMBLY SETTING BOLT |

| *3 | ENGINE MOUNTING INSULATOR LH | *4 | ENGINE WIRE |

| *5 | FLYWHEEL HOUSING UNDER COVER | *6 | FRONT ENGINE MOUNTING BRACKET |

| *7 | FRONT ENGINE MOUNTING INSULATOR | *8 | NO. 1 TRANSMISSION OIL COOLER HOSE |

| *9 | TORQUE CONVERTER ASSEMBLY | - | - |

| *a | BLACK COLOR: x 1 SILVER COLOR: x 5 | - | - |

.png) | Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) | .png) | N*m (kgf*cm, ft.*lbf): Specified torque |

.png) | Adhesive 1324 | .png) | Clutch spline grease |

| ★ | Precoated part | - | - |

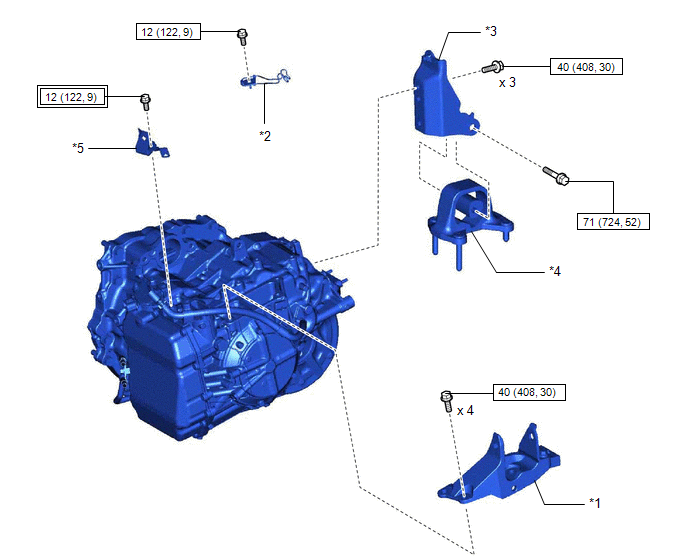

ILLUSTRATION

| *1 | ENGINE MOUNTING BRACKET LH | *2 | NO. 2 TRANSMISSION CONTROL CABLE BRACKET |

| *3 | REAR ENGINE MOUNTING BRACKET | *4 | REAR ENGINE MOUNTING INSULATOR |

| *5 | TRANSMISSION BREATHER SKIRT | - | - |

.png) | Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) | .png) | N*m (kgf*cm, ft.*lbf): Specified torque |

Installation

Installation

INSTALLATION PROCEDURE 1. INSTALL TORQUE CONVERTER ASSEMBLY (a) Turn the front oil pump drive gear so that either key is at the top and place a matchmark on the transaxle housing to indicate the po ...

Other materials:

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Safety Connect System: Green Indicator Remains Off

DESCRIPTION After engine switch on (IG), the DCM (telematics transceiver) will enter into self check mode. The manual (SOS) switch red indicator will illuminate for 2 seconds and turn off followed by the manual (SOS) switch green indicator illuminating and remaining on under normal operation. If nei ...

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Front Seat Outer Belt Assembly: Disposal

DISPOSAL CAUTION / NOTICE / HINT CAUTION: Before performing pre-disposal deployment of any SRS part, review and closely follow all applicable environmental and hazardous material regulations. Pre-disposal deployment may be considered hazardous material treatment. PROCEDURE 1. PRECAUTION CAUTION:

...

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Owners Manual

- For your information

- Pictorial index

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Lexus Display Audio system

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Repair Manual

0.0092