Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual: Instrument Panel Box Light and Footwell Light Circuit

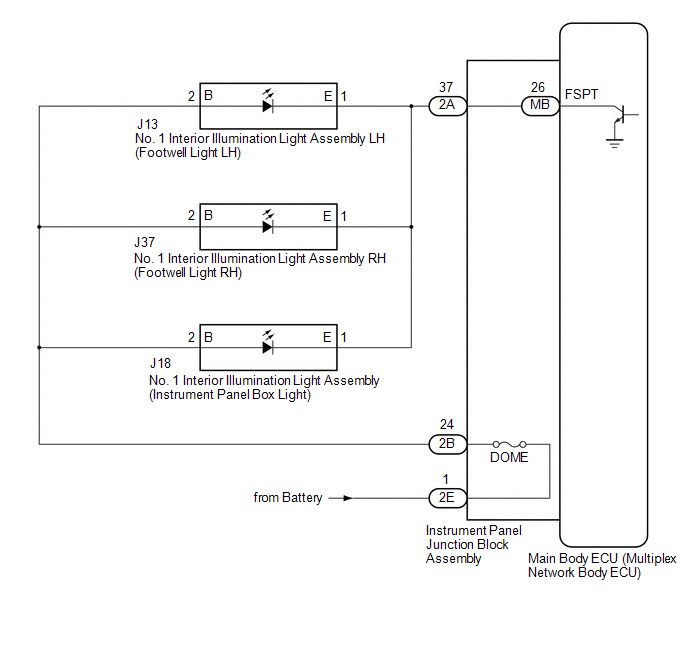

DESCRIPTION

The main body ECU (multiplex network body ECU) controls the instrument panel box light and footwell light.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Before replacing the main body ECU (multiplex network body ECU), refer to Registration.

Click here .gif)

.gif)

.gif)

PROCEDURE

| 1. | PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Start the engine.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / (desired system) / Active Test.

(e) Perform the Active Test according to the display on the Techstream.

Body Electrical > Main Body > Active Test| Tester Display | Measurement Item | Control Range | Diagnostic Note |

|---|---|---|---|

| Fr Foot Light | Footwell light and instrument panel box light | ON or OFF | - |

| Tester Display |

|---|

| Fr Foot Light |

OK:

Instrument panel box light and footwell lights comes on.

| OK | .gif) | PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

|

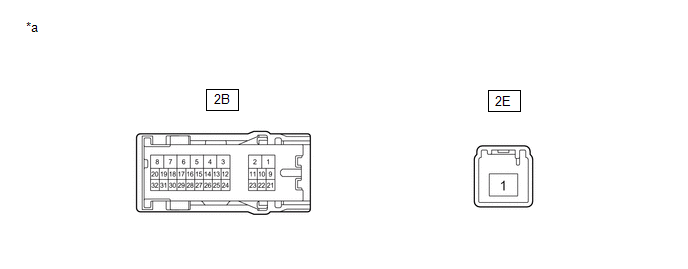

| 2. | CHECK HARNESS AND CONNECTOR (POWER SOURCE - INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY) |

(a) Disconnect the 2E instrument panel junction block assembly connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| 2E-1 - Body ground | Always | 11 to 14 V |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 3. | INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

(a) Disconnect the 2E instrument panel junction block assembly connector.

(b) Disconnect the 2B instrument panel junction block assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

| *a | Component without harness connected (Instrument Panel Junction Block Assembly) | - | - |

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| 2E-1 - 2B-24 | Always | Below 1 Ω |

| NG | .gif) | REPLACE INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

|

| 4. | CHECK HARNESS AND CONNECTOR (No. 1 INTERIOR ILLUMINATION LIGHT ASSEMBLY - INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY) |

(a) Disconnect the J13 No. 1 interior illumination light assembly LH connector.

(b) Disconnect the J37 No. 1 interior illumination light assembly RH connector.

(c) Disconnect the J18 No. 1 interior illumination light assembly connector.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| 2B-24 - J13-2(B) | Always | Below 1 Ω |

| 2B-24 - J37-2(B) | Always | Below 1 Ω |

| 2B-24 - J18-2(B) | Always | Below 1 Ω |

| J13-2(B) or 2B-24 - Body ground | Always | 10 kΩ or higher |

| J37-2(B) or 2B-24 - Body ground | Always | 10 kΩ or higher |

| J18-2(B) or 2B-24 - Body ground | Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

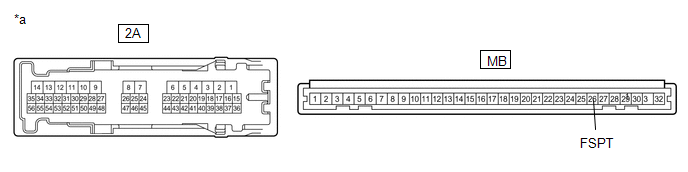

| 5. | CHECK HARNESS AND CONNECTOR (No. 1 INTERIOR ILLUMINATION LIGHT ASSEMBLY - INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY) |

(a) Disconnect the 2A instrument panel junction block assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| 2A-37 - J13-1(E) | Always | Below 1 Ω |

| 2A-37 - J37-1(E) | Always | Below 1 Ω |

| 2A-37 - J18-1(E) | Always | Below 1 Ω |

| J13-1(E) or 2A-37 - Body ground | Always | 10 kΩ or higher |

| J37-1(E) or 2A-37 - Body ground | Always | 10 kΩ or higher |

| J18-1(E) or 2A-37 - Body ground | Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 6. | INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

(a) Remove the instrument panel junction block assembly.

Click here .gif)

.gif)

.gif)

(b) Remove the main body ECU (multiplex network body ECU) from the instrument panel junction block assembly.

Click here .gif)

.gif)

.gif)

(c) Measure the resistance according to the value(s) in the table below.

| *a | Component without harness connected (Instrument Panel Junction Block Assembly) | - | - |

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| 2A-37 - MB-26 (FSPT) | Always | Below 1 Ω |

| OK | .gif) | REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

| NG | .gif) | REPLACE INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

Interior Light Switch Signal Circuit

Interior Light Switch Signal Circuit

DESCRIPTION The main body ECU (multiplex network body ECU) detects the condition of the door switch and front dome light switch. WIRING DIAGRAM CAUTION / NOTICE / HINT NOTICE: Before replacing the ma ...

Ambient Illumination Light Circuit

Ambient Illumination Light Circuit

DESCRIPTION The main body ECU (multiplex network body ECU) controls the ambient illumination lights. WIRING DIAGRAM CAUTION / NOTICE / HINT NOTICE:

Inspect the lights for circuits related to this ...

Other materials:

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Back Door Closer Ecu: Components

COMPONENTS ILLUSTRATION *A w/o Rear No. 2 Seat *B w/ Rear No. 2 Seat *1 BACK DOOR LOCK COVER *2 BACK DOOR TRIM BASE *3 BACK DOOR TRIM COVER LH *4 BACK DOOR TRIM COVER RH *5 BACK DOOR TRIM PANEL ASSEMBLY *6 BACK WINDOW UPPER PANEL TRIM *7 DOOR PULL HANDLE ...

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Combination Meter: Disassembly

DISASSEMBLY PROCEDURE 1. REMOVE COMBINATION METER GLASS (for Optitron Meter Type) (a) Disengage the 8 claws to remove the combination meter glass. 2. REMOVE COMBINATION METER GLASS (for TFT Meter Type) (a) Disengage the 9 claws to remove the combination meter glass. ...

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Owners Manual

- For your information

- Pictorial index

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Lexus Display Audio system

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Repair Manual

0.0152

.gif)