Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual: Inspection

INSPECTION

PROCEDURE

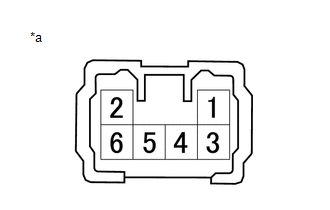

1. INSPECT NO. 2 SEAT CUSHION FRAME SUB-ASSEMBLY RH

| *a | Component without harness connected (No. 2 Seat Cushion Frame Sub-assembly RH) |

(a) Apply battery voltage to the lifter motor connector, and check that the No.2 seat cushion frame sub-assembly RH operates smoothly as follows.

OK:

| Battery Connection | Specified Condition |

|---|---|

| Battery positive (+) → Terminal 4 Battery negative (-) → Terminal 3 | Downward |

| Battery positive (+) → Terminal 3 Battery negative (-) → Terminal 4 | Upward |

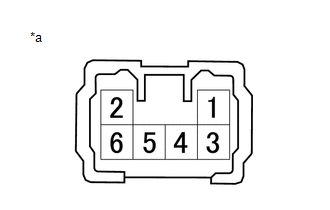

2. INSPECT NO. 2 SEATBACK FRAME SUB-ASSEMBLY RH

| *a | Component without harness connected (No. 2 Seatback Frame Sub-assembly RH) |

(a) Apply battery voltage to the reclining motor connector, and check that the No.2 seatback frame sub-assembly RH operates smoothly as follows.

OK:

| Battery Connection | Specified Condition |

|---|---|

| Battery positive (+) → Terminal 3 Battery negative (-) → Terminal 4 | Forward |

| Battery positive (+) → Terminal 4 Battery negative (-) → Terminal 3 | Backward |

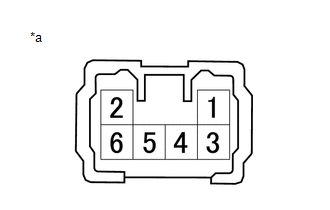

3. INSPECT NO. 2 SEAT CUSHION FRAME SUB-ASSEMBLY LH

| *a | Component without harness connected (No. 2 Seat Cushion Frame Sub-assembly LH) |

(a) Apply battery voltage to the lifter motor connector, and check that the No.2 seat cushion frame sub-assembly LH operates smoothly as follows.

OK:

| Battery Connection | Specified Condition |

|---|---|

| Battery positive (+) → Terminal 4 Battery negative (-) → Terminal 3 | Downward |

| Battery positive (+) → Terminal 3 Battery negative (-) → Terminal 4 | Upward |

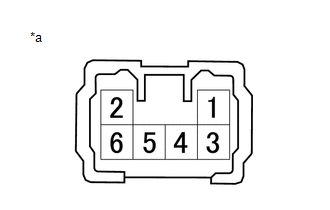

4. INSPECT NO. 2 SEATBACK FRAME SUB-ASSEMBLY LH

| *a | Component without harness connected (No. 2 Seatback Frame Sub-assembly LH) |

(a) Apply battery voltage to the reclining motor connector, and check that the No.2 seatback frame sub-assembly LH operates smoothly as follows.

OK:

| Battery Connection | Specified Condition |

|---|---|

| Battery positive (+) → Terminal 3 Battery negative (-) → Terminal 4 | Forward |

| Battery positive (+) → Terminal 4 Battery negative (-) → Terminal 3 | Backward |

Components

Components

COMPONENTS ILLUSTRATION *1 DECK BOARD ASSEMBLY *2 NO. 1 DECK BOARD *3 REAR NO. 4 FLOOR BOARD *4 TONNEAU COVER ASSEMBLY ILLUSTRATION *A w/o Woofer *B w/ Woofer *1 ...

Installation

Installation

INSTALLATION CAUTION / NOTICE / HINT CAUTION: Wear protective gloves. Sharp areas on the seat frame may injure your hands. PROCEDURE 1. INSTALL REAR NO. 2 SEAT ASSEMBLY (a) Place the rear No. 2 seat a ...

Other materials:

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Meter / Gauge System: Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART Meter / Gauge System DTC No. Detection Item Memory Note Link B1321 Lost Communication with EMV DTC stored - B1326 Lost Communication with Clock Device (Local-CAN) DTC stored - B1500 Fuel Sender Open Detected - - ...

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Rear Bumper (w/ Rear No. 2 Seat): Disassembly

DISASSEMBLY PROCEDURE 1. REMOVE REAR CENTER ULTRASONIC SENSOR (w/ Intuitive Parking Assist System) Click here 2. REMOVE REAR CORNER ULTRASONIC SENSOR (w/ Intuitive Parking Assist System) Click here 3. REMOVE REAR CENTER ULTRASONIC SENSOR RETAINER (w/ Intuitive Parking Assist System) Click here ...

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Owners Manual

- For your information

- Pictorial index

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Lexus Display Audio system

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Repair Manual

0.0105