Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual: Replacement

REPLACEMENT

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during front drive shaft oil seal LH and front drive shaft oil seal RH removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced| Replacement Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

|---|---|---|---|

| Front wheel alignment adjustment | Calibration |

| |

PROCEDURE

1. REMOVE FRONT WHEEL OPENING EXTENSION PAD LH

Click here .gif)

2. REMOVE NO. 3 ENGINE UNDER COVER

Click here .gif)

3. REMOVE FRONT FENDER APRON SEAL LH

Click here .gif)

4. DRAIN AUTOMATIC TRANSAXLE FLUID

| (a) Remove the refill plug and gasket from the automatic transaxle case sub-assembly. |

|

| (b) Using a T40 "TORX" socket wrench, remove the drain plug and O-ring from the transaxle housing. |

|

| (c) Using a 17 mm straight hexagon wrench, remove the overflow plug and O-ring from the transaxle housing and drain the automatic transaxle fluid. |

|

(d) Using a 17 mm straight hexagon wrench, install a new O-ring and the overflow plug to the transaxle housing.

Torque:

47 N·m {479 kgf·cm, 35 ft·lbf}

(e) Using a T40 "TORX" socket wrench, temporarily install the O-ring and drain plug to the transaxle housing.

HINT:

Reuse the old O-ring as the drain plug will be removed again to adjust the automatic transaxle fluid level.

(f) Temporarily install the gasket and refill plug to avoid automatic transaxle fluid spillage.

HINT:

Reuse the old gasket as the refill plug will be removed again to adjust the automatic transaxle fluid level.

5. REMOVE FRONT DRIVE SHAFT ASSEMBLY

Click here .gif)

6. REMOVE DRIVE SHAFT BEARING BRACKET

Click here .gif)

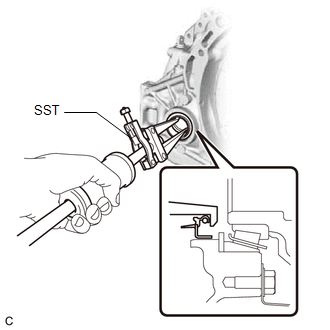

7. REMOVE FRONT DRIVE SHAFT OIL SEAL LH

| (a) Using SST, remove the front drive shaft oil seal LH from the automatic transaxle case sub-assembly. SST: 09308-00010 NOTICE: Be careful not to damage the automatic transaxle case sub-assembly. |

|

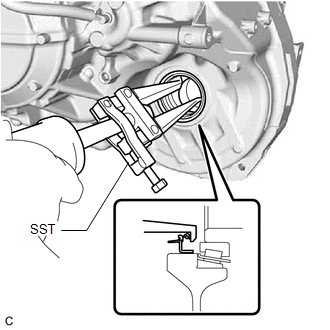

8. REMOVE FRONT DRIVE SHAFT OIL SEAL RH

| (a) Using SST, remove the front drive shaft oil seal RH from the transaxle housing. SST: 09308-00010 NOTICE: Be careful not to damage the transaxle housing. |

|

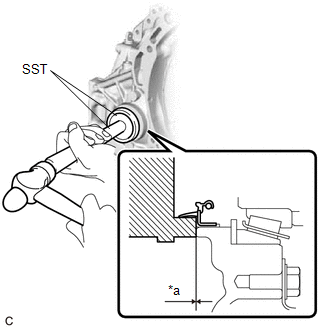

9. INSTALL FRONT DRIVE SHAFT OIL SEAL RH

| (a) Using SST and a hammer, install a new front drive shaft oil seal RH to the transaxle housing. SST: 09316-60011 09316-00011 SST: 09950-70010 09951-07150 Standard Depth: -0.5 to 0.5 mm (-0.0197 to 0.0197 in.) NOTICE:

|

|

(b) Coat the lip of the front drive shaft oil seal RH with MP grease.

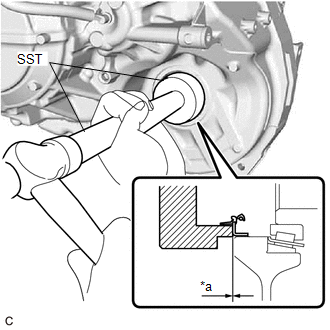

10. INSTALL FRONT DRIVE SHAFT OIL SEAL LH

| (a) Using SST and a hammer, install a new front drive shaft oil seal LH to the automatic transaxle case sub-assembly. SST: 09316-10010 SST: 09950-70010 09951-07100 Standard Depth: -0.5 to 0.5 mm (-0.0197 to 0.0197 in.) NOTICE:

|

|

(b) Coat the lip of the front drive shaft oil seal LH with MP grease.

11. INSTALL DRIVE SHAFT BEARING BRACKET

Click here .gif)

12. INSTALL FRONT DRIVE SHAFT ASSEMBLY

Click here .gif)

13. ADJUST AUTOMATIC TRANSAXLE FLUID

Click here .gif)

14. INSPECT FOR FLUID LEAK

15. INSTALL FRONT FENDER APRON SEAL LH

Click here .gif)

16. INSTALL NO. 3 ENGINE UNDER COVER

Click here .gif)

17. INSTALL FRONT WHEEL OPENING EXTENSION PAD LH

Click here .gif)

Components

Components

COMPONENTS ILLUSTRATION *1 FRONT WHEEL OPENING EXTENSION PAD LH *2 NO. 3 ENGINE UNDER COVER *3 FRONT FENDER APRON SEAL LH - - ILLUSTRATION *1 DRIVE SHAFT BEARING BRACKET ...

Oil Pump

Oil Pump

...

Other materials:

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Navigation System: Certification ECU Vehicle Information Reading/Writing Process Malfunction (B15F7)

DESCRIPTION This DTC is stored when items controlled by the certification ECU (smart key ECU assembly) cannot be customized via the navigation system vehicle customization screen. HINT: The certification ECU (smart key ECU assembly) controls the smart access system with push-button start (for Entry ...

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Smart Access System With Push-button Start (for Start Function): Data List / Active Test

DATA LIST / ACTIVE TEST DATA LIST HINT: Using the Techstream to read the Data List allows the values or states of switches, sensors, actuators and other items to be read without removing any parts. This non-intrusive inspection can be very useful because intermittent conditions or signals may be dis ...

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Owners Manual

- For your information

- Pictorial index

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Lexus Display Audio system

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Repair Manual

0.0123

.png)

.png)

.png)