Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual: Inspection

INSPECTION

PROCEDURE

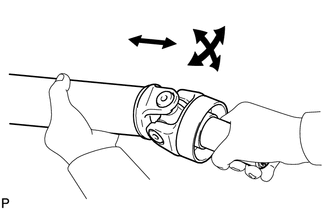

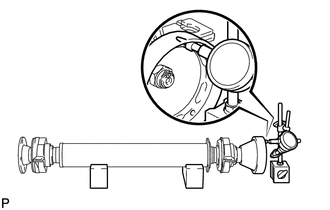

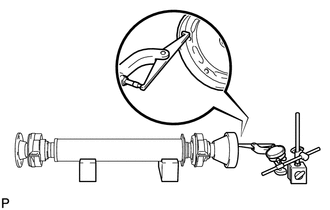

1. INSPECT SPIDER BEARING

| (a) Check that the spider bearing rotates smoothly. |

|

| (b) Check that there is no play in the spider bearing. If necessary, replace the propeller with center bearing shaft assembly. |

|

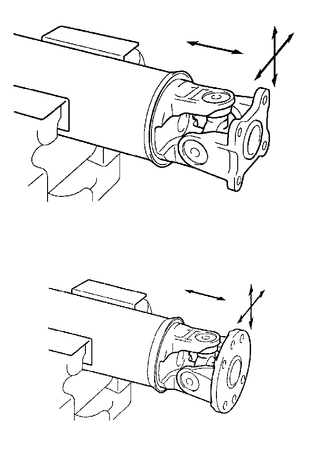

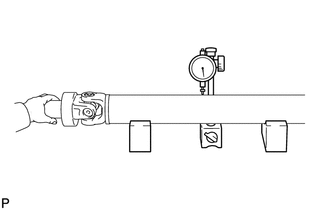

2. INSPECT INTERMEDIATE SHAFT ASSEMBLY

| (a) Using a dial indicator, measure the runout of the intermediate shaft assembly. Maximum Runout: 0.4 mm (0.0157 in.) NOTICE: The dial indicator must be set at a right angle to the center of the intermediate shaft assembly. If the shaft runout exceeds the maximum, replace the propeller with center bearing shaft assembly. |

|

| (b) Using a dial indicator, measure the runout of the universal joint flange (for front side). Maximum Runout: 0.1 mm (0.00394 in.) If the shaft runout exceeds the maximum, replace the propeller with center bearing shaft assembly. |

|

| (c) Using a dial indicator, measure the runout of the universal joint flange (for rear side). Maximum Runout: 0.1 mm (0.00394 in.) If the shaft runout exceeds the maximum, replace the propeller with center bearing shaft assembly. |

|

| (d) Using a dial indicator, measure the runout of the universal joint flange (for rear side). Maximum Runout: 0.1 mm (0.00394 in.) If the shaft runout exceeds the maximum, replace the propeller with center bearing shaft assembly. |

|

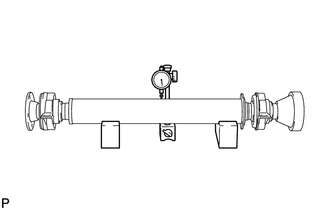

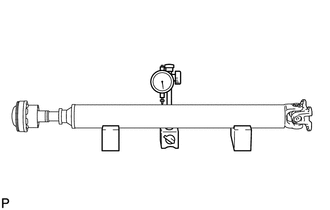

3. INSPECT PROPELLER SHAFT ASSEMBLY

| (a) Using a dial indicator, measure the runout of the propeller shaft assembly. Maximum Runout: 0.4 mm (0.0157 in.) NOTICE: The dial indicator must be set at a right angle to the center of the propeller shaft assembly. If the shaft runout exceeds the maximum, replace the propeller with center bearing shaft assembly. |

|

4. INSPECT REAR PROPELLER SHAFT ASSEMBLY

| (a) Using a dial indicator, measure the runout of the rear propeller shaft assembly. Maximum Runout: 0.4 mm (0.0157 in.) NOTICE: The dial indicator must be set at a right angle to the center of the rear propeller shaft assembly. If the shaft runout exceeds the maximum, replace the propeller with center bearing shaft assembly. |

|

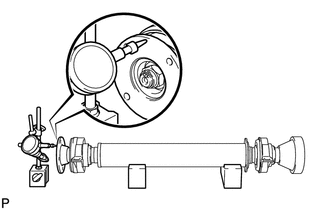

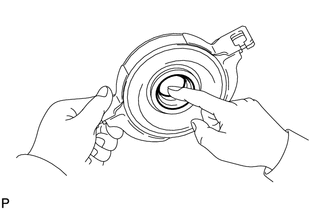

5. INSPECT CENTER NO. 2 SUPPORT BEARING ASSEMBLY

| (a) Turn the center No. 2 support bearing assembly by hand. |

|

(b) Check that the center No. 2 support bearing assembly turns smoothly, and check that the seals are not cracked or damaged.

If the center No. 2 support bearing assembly is damaged or worn, or does not turn smoothly, replace it.

Removal

Removal

REMOVAL PROCEDURE 1. REMOVE NO. 2 ENGINE UNDER COVER Click here 2. REMOVE FRONT FLOOR COVER LH Click here 3. REMOVE FRONT CENTER FLOOR COVER for TMC Made: Click here for TMMC Made: Click he ...

Installation

Installation

INSTALLATION PROCEDURE 1. TEMPORARILY TIGHTEN PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY (a) Remove SST from the transfer assembly. (b) Insert the propeller with center bearing shaft ...

Other materials:

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Navigation System: D-Seat ECU Vehicle Information Reading/Writing Process Malfunction (B15F8)

DESCRIPTION This DTC is stored when items controlled by the main body ECU (multiplex network body ECU) cannot be customized via the navigation system vehicle customization screen. HINT: The main body ECU (multiplex network body ECU) controls the front power seat control system (w/ Memory) related it ...

Lexus RX (RX 350L, RX450h) 2016-2026 Repair Manual > Shift Lever: Removal

REMOVAL PROCEDURE 1. SECURE VEHICLE (a) Fully apply the parking brake and chock a wheel. CAUTION:

Make sure to apply the parking brake and chock a wheel before performing this procedure.

If the vehicle is not secure and the shift lever is moved to N, the vehicle may suddenly move, possibly resu ...

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Owners Manual

- For your information

- Pictorial index

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Lexus Display Audio system

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Lexus RX (RX 350L, RX450h) 2016-{YEAR} Repair Manual

0.0136